|

Miller County Milling

IBERIA MILL & ELECTRIC LIGHT COMPANY

By Peggy Smith Hake

In early 1908, the Iberia Mill and Electric Light Company was organized. On January 20, 1908, Articles of Agreement were drawn up at Iberia by a Board of Directors. They began the old mill and electric company with a capital stock of $9,000 which included 90 shares with the value of $100 each. The Board of Directors included Charles W. Farnham, president; John L. Irwin, vice president; Frank Topping, secretary; John S. Casey, treasurer; Miles J. Davidson, David P. Farnham, and William A. Von Gremp, members.

The shareholders who purchased the shares at $100 each were the following:

- SHAREHOLDERS NO. OF SHARES PURCHASED

- Miles J. Davidson 10

- Wm. A. von Gremp 10

- John S. Casey 10

- Frank Topping 10

- John L. Irwin 10

- William L. Farnham 10

- Charles W. Farnham 10

- James A. Eads 10

- William H. Irwin 3

- David P. Farnham 2 1/2

- George A. Mace 2 1/2

- Lewis F. Atwell 1

- William T. Hedges 1

The "Articles of Agreement" were filed for record at the Miller County courthouse on January 30, 1908 by W. M. Bear, Deputy Recorder for Charles E. Howell, Recorder of Deeds.

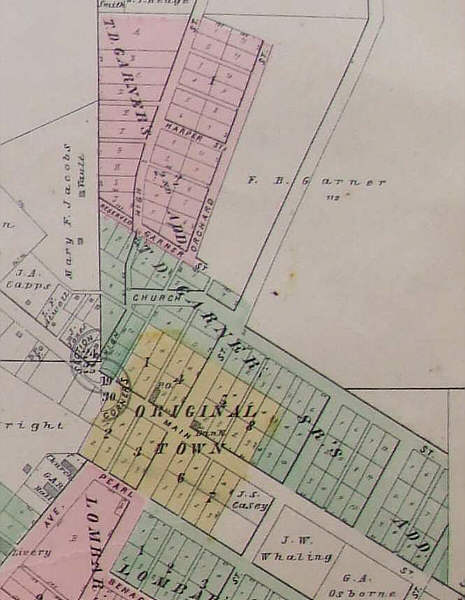

The land on which the mill and electric light company was built was owned by Miles and Electa Davidson and included Lots 1, 2, 3, and 4 in Block 3 of Lombar's Second Addition to the Original Town of Iberia. The mill faced Thompson Street on the west and Benage Street on the south and was directly behind the old four-room elementary school. Water was piped into the old mill building from a large spring that was directly east of the mill.

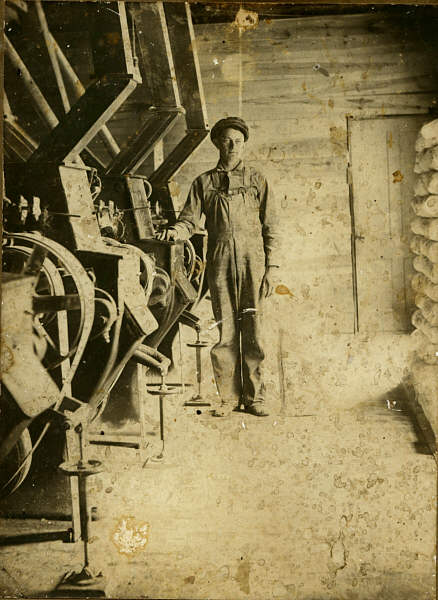

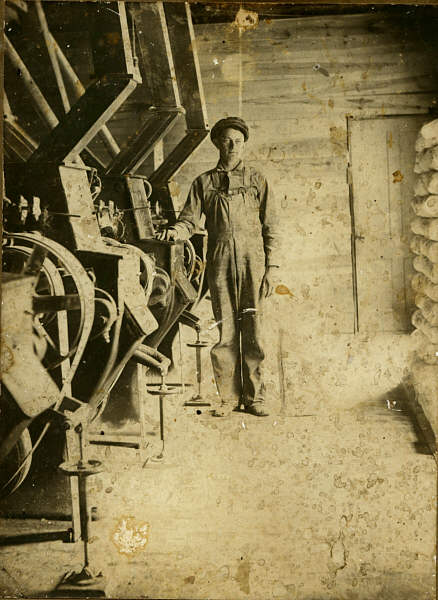

This is believed to be Bennett or Jeff Skaggs. They owned the old mill in the 1920’s & 1930’s. Jeff Skaggs was killed in this mill in an accident in the early 1930’s. The building has been gone now for many years but I remember the old structure, which was huge and deserted, standing there in the early 1940s when I was attending the Iberia elementary school.

News Tribune Article - Feb. 27, 2008

HISTORY OF BRAYS MILL

By Marge Handley, Iberia, Missouri

Bray's Mill photo was taken in 1969 by Jim Martin. Bray's Mill was built between 1862 and 1864. Thomas Bray financed its construction - hence, its title. The land on which it sits was deeded as a land grant from the U.S. general Land Office on 1 July 1845. This first mention in the abstract was filed in Miller County on 3 May 1901 and was signed by J. Knox Walker for the President of the United States, James Knox Polk.

Over approximately 145 years, the mill has changed ownership dozens of times. The abstracts state names, such as, Larkin Osburn, David Winingham, Mesach Rowden, John and William Rowden, James Buchanan, President of the United States, U.S. Grant (again, our President), several members of the Bray family , Guy Smith, and Isaac Smith. The entire list is too numerous to mention here.

In 1889 Tom Bray constructed a roller mill near the original water-powered grist mill. During harvest there was always a back-log of work for the mills. Overnight camping at the mill site was common as people slept under wagons and large bushes for protection from the falling dew and mosquitoes. About this time Will Morrow rebuilt the wooden water wheel and helped in overhauling the older mill.

Bray's Mill has been sold for as little as $1.00 or for as much as $40,000. It has been sold to pay back taxes. Other purchase prices were $10.00, $25.00, and $1500.00.

Thomas A. Bray died on 6 November 1906 in the town of Pay Down, Maries County, Missouri. He left behind, his wife, Mahala, 4 sons, and 5 daughters.

For most of its existence, Bray's Mill has supported and survived as a grist mill. However, it has also served as a Post Office, a safe haven for tired travelers, a dentist office (operated by Guy Smith), and an ice manufacturing plant from 1931 to 1942. Isaac Smith produced 16-300 pound blocks of ice each 24 hours and delivered ice to the surrounding community. He made ice from spring water which filled 16 ice forms. Ammonia coils surrounded the forms and froze the water into ice. The ammonia was pumped by compressors which were powered by the overshot water wheel. The springs produced approximately 700 gallons of water per minute (and still do). Bray's Mill is located 31/4 miles east on Highway 42 from Iberia. From Iberia, cross Kenser Creek and take the first gravel road to the left. Proceed 2/10 of a mile to a Y junction. Take the left leg. You're there!

HISTORY OF BRAYS MILL IN RICHWOODS TOWNSHIP

by Peggy Smith Hake

(printed in ANCESTORS, The New Iberian, 10 Feb 1982

Among the earlier settlers in the area northeast of Iberia was a man named Larkin Osbourn. He entered some acreage in the early 1840s and had it recorded at the land office on 1 July 1845. Larkin and his wife, Delila, sold most of their land in 1848 to Meshac Rowden, a native of Henry County, Virginia. Meshac must have lived somewhere in the general area of this property because when he died, about 1853, he was the first person buried in old Brays Cemetery. The heirs of Meshac Rowden were: William R. Rowden, John Rowden, and Elletha Rowden Johnston. William and his wife, Abigail (Renfrow) and Elletha and her husband, Joseph Johnston, sold their share of the inheritance to John Rowden in 1853.

The next year, John/Jack Rowden erected a water mill on the site, which was used for grinding and crushing different grains. It has been said that John Rowden sold the mill to a Mr. Wheeler in 1860, before the Civil War, and it was operated by two German emigrants named Goodmann/Gudeman and Lampe. For sometime it was called "Wheeler's Mill". I could find no transfer of land from Rowden to Wheeler in the courthouse records, but did find a deed, dated 8 Oct 1864 from John and Martha Jane Rowden (who were living in Crawford County, MO) to Thomas A. Bray of Maries County, MO....Thomas and his wife, Mahala, had a large family of nine children and they owned the woolen mill and dye plant at the small Gasconade river town called Pay Down.

The Brays hired Joseph/Joe Slawson of Maries County to run the Miller County mill during the Civil War years and, later it was operated by Josh Stephens. Joseph Slawson may have the same man who came to Miller County and settled in the Alder Springs community. He was a son of Joseph Arnold Slawson, a native of North Carolina. Earlier the Slawsons were in Jasper County, MO before moving to central Missouri.

About 1877, Bray hired Albert Arendall to run the mill and the Arendall family moved from Pay Down to Miller County. It was at that time that "Brays Mill" became known as a permanent location and has remained so all these years; the name suggested by Al Arendall. The community around Brays Mill was also called Brays and at one time there was a one-room school that sat on a hill to the east of old Brays. The settlement had a general store, blacksmith shop, and post office that existed from 1894-1923. On a 1904 map, Brays is recorded standing near an old road that ran from Hancock in Pulaski County (an old mail route), past the Atwell community in southeast Miller County and on northwest to Brays. Further north the old road passed by the post offices named Blyze, Claxby, and crossed the Big Tavern creek then onward to St. Elizabeth. Old Brays began to die out in the 1940s after almost 100 years of existence. All that remains today is the old /general/grocery store, which long ago was abandoned to nature and its elements.

In 1889, a roller mill was built near the water mill. This is the same four-storied building standing today. The roller mill accommodated folks from all over Miller County and the neighboring counties of Maries, Osage, Pulaski, and perhaps others as well.

Albert and Helen (Goforth) Arendall continued to manage and operate the Brays Mill for a good many years. Albert was assisted by his son, Allen Arendall, and a son-in-law, Charles Smith. Sometime in the early years of the 1900s, Thomas Bray died and his wife, Mahala, and their children sold all their interests in the mill to Albert and Helen Arendall. In 1912, Albert sold the mill to Arch and Charley Helton and they ran it for a while, but later sold it back to Albert Arendall. The Arendalls finally gave up the operation of the mill in 1919 and, at that time, sold the land to their grandchildren: Guy, Mabel, and Laura Smith. In 1922, the Smith girls sold the land to Guy and in 1929 he decided to construct an ice plant at the Brays Mill site. By 1931, it was ready to be used and ice production began on a large scale. Deliveries of 1500 pounds of ice per day were transported to Iberia and surrounding area. Unfortunately, the popular electric refrigerator replaced this ice-making business and it is now just another long-ago memory.

Today, Brays Mill stands on the same spot. Her old wooden wheel no longer turns, but she stands so majestic in a beautiful valley surrounded by ancient hills that whisper a haunting melody as the winds and breezes whistle up the valley floor. You can almost hear the 'hustle and bustle' of a by-gone day with the water wheel turning and creaking in the sunlight. It is such a pleasant trip to drive through this region that is so rich in history.

NOTE: In 2008, Brays Mill is the home of Marge Handley. It has been beautifully renovated, the old water wheel has been enclosed behind glass, and the outside walls covered with aluminum siding. It is still a comfortable home for the Handley family and an asset to the countryside of the Big Tavern Valley in the Big Richwoods.

BRIEF HISTORY OF ANCHOR MILLING COMPANY

The Anchor Milling Company dates back to 1876 when William Hauenstein, Sr. purchased a saw and grist mill near the mouth of Gum Creek above Tuscumbia. At that time corn was ground on 'mill stones'. Our great-grandfather became aggravated at the inconvenience when his team of oxen in hot weather would stop to cool off in a pond on the way to the mill and he decided, about 1880, to move the business down the river to a location in what is now Riverside Park. About 1887, stands of steel rollers were purchased and installed. They replaced the stone burrs which required sharpening every week. After the rollers were installed, it was conceded that the mill was one of the most up-to-date in the Mid-West. Wheat flour was sold to Jefferson City and other places in a fifty mile radius.

The company was incorporated in 1897 and the name, Anchor Milling Company, was taken after the Anchor Steamboat Line that ran from St. Louis to New Orleans. Mr. J. R. Wells was the first president of the Company and in 1898, the Steamer J. R. Wells, was launched, named in honor of the Company president. The steamer made regular trips from Tuscumbia to Osage City and from Tuscumbia to Old Linn Creek. Several trips were made to St. Louis. At the time of incorporation, the first lumberyard was established.

In 1894, a modern flour mill was built on the river in the east end of Tuscumbia. Dozens of wagons camped at the mill for as many as 24 hours waiting to toll their wheat for flour.

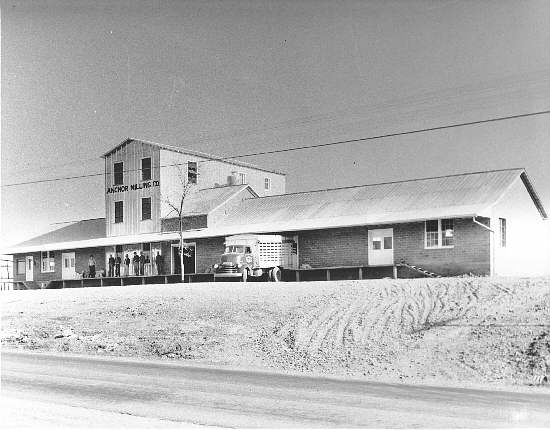

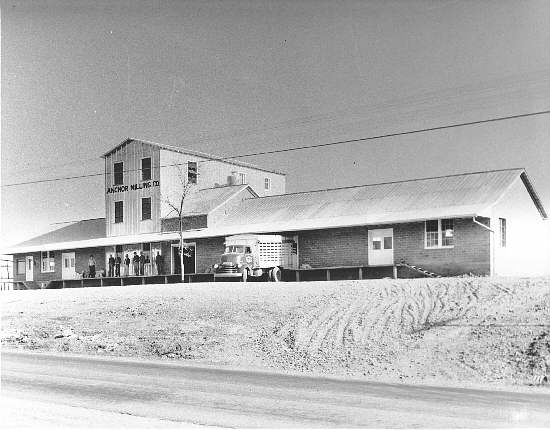

Anchor roller Mills This building, near the Osage River, served Anchor Milling Company for or some 60 of their 100 years in Tuscumbia. Phillip Hauenstein selected this site in 1894 for the new roller mills, higher than Riverside Park where the milling facilities had been located, because he thought the Osage would never reach it. The next year the flood of 1895 came. A timber from this building showing the depth and date of that 1895 flood, was used in the Anchor Milling building in Eldon where the carved record is visible in the basement.

Anchor Milling lumber office and mill Depth was far short, though, of that reached by the disastrous flood of 1943. This building was located downstream and across a ravine, crossed by bridge in the foreground from the hardware building which still stands on the river bank and is used as vacation property.

The flour milling business was discontinued, but the feed mill was moved atop the hill to a new building on Hwy. 52 in 1949 near the rock hardware building erected earlier. This roller mills building shown here, however was continued in use for feed storage for about a half dozen more years until it was torn down. In 1960, pelleting equipment was installed along with equipment for handling bulk feed. This mill was sold in 1976

Eldon facilities In 1956, the Company purchased a site at Eldon at the corner of Highway 52 and 5th Street and constructed a tile building. A small milling operation was installed in the east end of the building. Jim McNeeley was the first manager of the Eldon business.

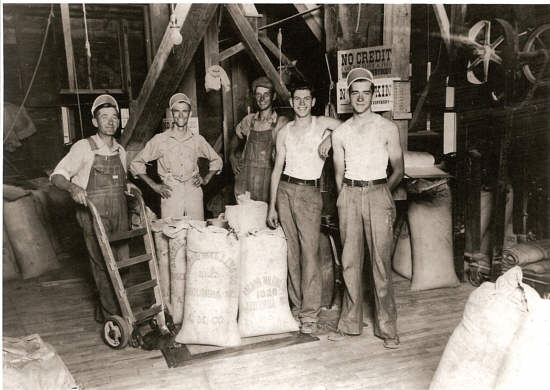

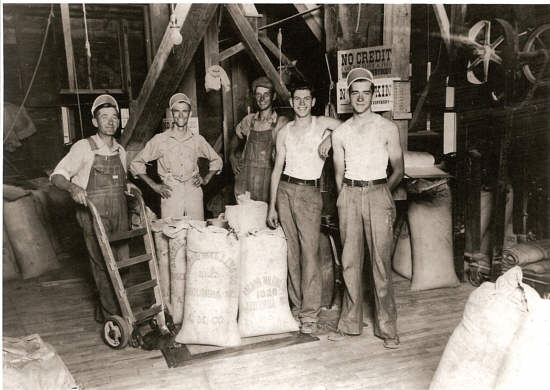

L-R: Homer Lee Wright, Tolliver Lawson, Wayne Hawken, Bill Hall, Bamber H. Wright

Summer 1937 C. B.Wright was affiliated with the Company for more than 50 years, as river boat pilot, manager and as president. Homer Lee Wright was miller for many years and salesman. Bamber and Homer Wright were fourth generation family members to be associated with Anchor Milling Co.

NOTE:

The Anchor Milling Company is no longer in existence. The beautiful, native rock building on Highway 52 in Tuscumbia was purchased from the Wright family by the Miller County Historical in 1988 and became the new home of the Miller County Museum, with a grand opening on June 2, 1991.

--Information and photographs for this article were provided by Bamber Wright

WRIGHT'S MILL

By James E. Thompson

When I was a small boy, I recall one May day my father had sheared the sheep. After he had bundled the wool all up, he tied it on the back of the buckboard. He then hitched old Sealum (our horse) up to the buckboard, got me up in the seat beside him, and we took off for the old water mill (carding machine). It was located about three miles north of Tuscumbia on the Little Saline Creek, and was owned and operated by Lee Wright and his sons.

When we got there, it was an exciting and thrilling sight to me to see the water pouring over the big wheel, turning it. And the spring had been dammed up causing it to form a pool that looked to be 8 or 10 feet deep, and had bass swimming around in it. In the old water mill there was a grist mill upstairs and a carding mill below. The wool was carded or combed out nice and then made into rolls. The rolls, in turn, were taken home and spun into yarn.

Lee Wright started operations here several years before the turn of the century. And the old mill was closed down in the year 1906.

In the autumn of 1905, there came a big rise in the creek; it damaged the old water mill by washing out a big hole under the wheel and a lot of drift and debris between the mill and spring. This was known as the "pumpkin rise" and was remembered by that name for years. There were pumpkins scattered everywhere. You could see them on top of drifts and along the edge of where the high water had been.

The next year Lee Wright engaged Tom Harrison, and the mill was run by steam for a year by Tom's thrashing steam engine, but was closed down completely in 1906. A few years later the old water mill was razed, and is now passed into history many years ago. The burrs of the old mill that ground the grain are encased in the front wall of the Anchor Milling Co. of Tuscumbia.

Although the old mill passed into history many years ago, yet in my mind I still have a mental picture of the old w3ater mill and the way the place looked to me the day I was there with my father when I was a 5-year-old boy in the year 1898, some 80 years ago. I can still see the old mill house, a 1 1/2 story rustic building standing there in the trees by the spring, and the spring sending forth a sluice of water down a trough to the big wheel that powered the machinery…and my father standing at the door entrance talking to Lee Wright…and then there was old Sealum hitched to the buckboard and tied to an apple tree nearby. With all this in mind, it gives me a nostalgic feeling and brings back fond memories of a bygone day.

The old water mill has come and gone, and the ones who operated it have also come and gone; but the big spring is still there, as big and powerful as ever boiling up from the ground and sending off a fount of sparkling water to gladden all living things. As it goes murmuring on and on, it tends to echo the words of Alfred Tennyson in his poem, "Song of the Brook," which reads, "Men may come and men may go, but I go on forever.

The old Water Mill-carding machine and grist mill located three miles north of Tuscumbia on the Little Saline Creek, owned and operated by Lee Wright.

Wright's Carding Mill Visitors are Billie Harrison and his Sunday school class from the Christian Church at Tuscumbia. Seated from left are (maiden names) Gardia Swanson, Gretchen Bacon, Anna McBride, Anna Clark, Hortense Swanson, Lura Clark and Maude Clark. Standing behind: Ethyl Moles and Billie Harrison. Over on right; Lee Wright and son, Charley. Photo taken in the year 1903.

NOTE:

The old grist mill and carding machine was built and operated by James Lawrence Wright circa 1895. It was built on his property three miles north of Tuscumbia and located a short distance south of the old one-room Wright school house in Saline Valley, above the Saline Creek. Additionally, it was due south of the present day Saline Valley Church of Christ which I believe James L. Wright probably helped build sometime between 1860 and bought from the government shortly after his arrival in Miller County. The land purchase is recorded in the Bureau of Land Management records. The church, the old school house and the former Wright homestead is about one mile east of the old Kallenbach farm site which today is a Missouri State historical site because it has remained in the Kallenbach family for 140 years.

For additional information, please refer to "C.B. Wright Diaries" on our "Publications" page.

THOMAS D. GARNER ROLLER MILL

By Peggy Smith Hake

(printed in The New Iberian, 20 Oct 1982)

It was in the early 20th century, circa 1903-05, that the town of Iberia was rocked by a mighty explosion. Thomas D. Garner and Son Roller Mills were destroyed when the boiler, in a low-water stage, exploded and a great deal of damage occurred. Luckily the workers were given warning in ample time to evacuate the building and no one was injured. It was never proven, but there were indications it may have been a case of sabotage. Hugh Garner and Roy Brown were running the Roller Mills at the time of the explosion. Hugh was noted as a competent millright who had set up the machinery and Roy was the miller. It was told to me by Cass Farnham, a former Iberian, that the force of the explosion was so tremendous that a piece of timber from the mill's wall flew through the air and crashed through the walls of the Bank of Iberia sitting over a half-block away. A few years later, Roy Brown erected a flouring mill across the street toward the west of Garner's mill.

Garner Mill The mill was built by Thomas D. Garner and his son, Hugh McCoin Garner. It was located in an area almost directly north of today's Friendship Hall and the Loren Adams home and east of the old Hedges Beauty Shop.

Thomas D. Garner was born in North Caroline 10 Feb 1821. As a young man he ventured into Tennessee and there he married his wife, Mary Ann. She was a native of Tennessee, born 15 Oct 1834. They moved on into Arkansas as a young couple and lived for awhile before traveling north into Missouri. They were the parents of at least five children: John B. 1862-1863; James H. 1868-1870; Hugh McCoin b 25 Apr 1870; Cyrus W. 1886-1887; and Mary C. 1887-1888. Hugh was their only child who lived into adulthood.

Thomas D. Garner opened a grocery store in Iberia prior to 1870 and listed himself as a dry goods merchant. Apparently he was a successful businessman with his merchandising enterprises. He and Mary Ann built a beautiful home in Iberia, the former home of the David Vineyard family. Hugh Garner, the son, married Stella Moore, daughter of Dr. John H. Moore, a druggist in Iberia. Dr. Moore was a native of Virginia, born there in 1846. Hugh and Stella built their home on the location of the David Farnham residence. Stella Moore Garner was the first graduate of the Iberia Academy in 1893 at the age of 19 years.

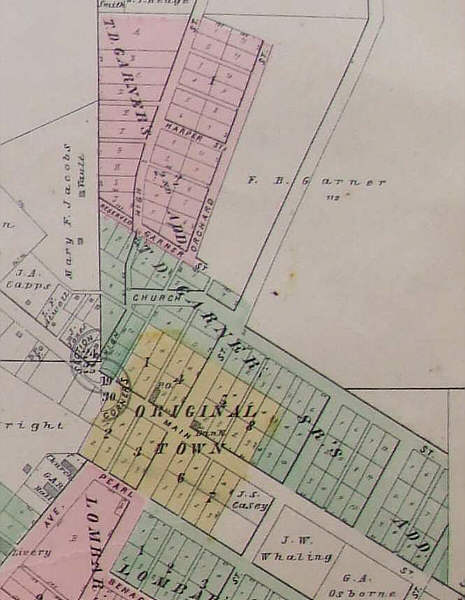

Stella Moore Thomas and Mary Ann Garner platted two additions to the original town of Iberia. The land laid north and east of the original town platted in 1859 by Henry Dickerson. They also owned some lots in the original town and sold off a corner of Lot 2, Block 5 to John Casey in 1897. In 1899, John sold the same parcel of land to the new Bank of Iberia. The town's first bank was built on the southeast corner of Main and St. Louis streets. Years ago the old bank building was moved to Lombar Street and today it is the home of Catron's Electric Shop.

Iberia Garners additions Thomas D. Garner died at Iberia in January 1906, sometime after the destruction of his mill. Mary Ann died one year later in January 1907. She had reached the age of 72 years and Thomas had lived to be 85 years old. I do not know for sure where Hugh and Stella resided in later years or if they left Iberia. The entire Garner family including Thomas, Mary Ann, Hugh, Stella and the infant children, are all buried in a large family plot in the Iberia Cemetery.

The Garner family was an important part of Iberia's early history and heritage because they were her merchants and millers. Today I know of no descendants of this family, although they may exist. I would hope their lineage did not cease with the death of Hugh Garner in 1955.

My sincere thanks are conveyed to the following persons whom I interviewed and to whom I owe so much for their marvelous memories of the Iberia by-gone days: Ms. Edna Jones, Arthur Perkins, David Farnham, Cass Farnham.

Ulman Milling Company

The Ulman Milling Co. was located at the south end of town, which was last operated by Lou McCommons and Rufus Crismon. It ran day and night supplying flour and meal to its customers. The milling company was sold to the Missouri State Penitentiary and was transported to Jefferson City across the Osage River at Tuscumbia which at the time was spanned by a wooden "swinging bridge". The last load which was the steam boiler, broke through the bridge with the back tires. They had to jack the tires back onto the bridge and one of the prison trustees who was assisting with the moving, volunteered to drive the load the remainder of the way across the bridge. For this his sentence was decreased by a number of years, enough to make him a free man.

Ulman Milling Company

Olean Milling

In 1881, Joseph Gattermeir came to Olean and with two brothers-in-law, took charge of the Buckeye Mill flouring mill just north of the town. Joseph Gattermeir was a native of Austria who came to this country with his parents in 1855, and learned the milling business in Morgan County. At the age of 14 he went to work with Brown Brothers at Cave Mills, and learned the trade of wool carding. After five years in this trade, he was apprenticed to August Zwanzig to learn the milling business.

On February 20, 1881 he formed a partnership with his two brothers-in-law, Edwin and Bernhardt Zwanzig, and bought the milling property near what is today the town of Olean. This was more than a year before a post office was established there in July, 1882, and the same year that survey was begun for the Missouri Pacific's Bagnell Branch Rail Line.

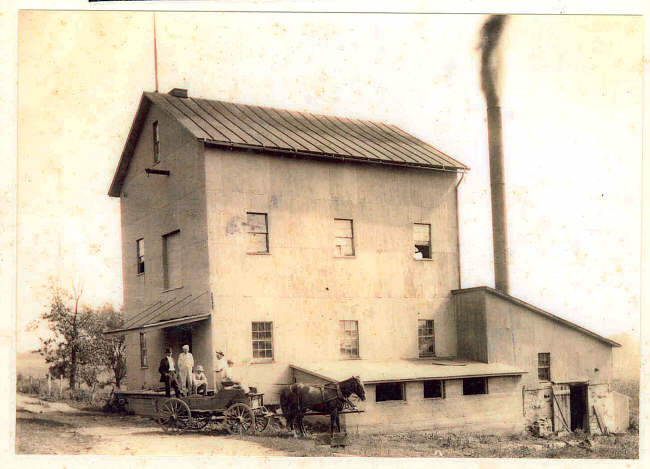

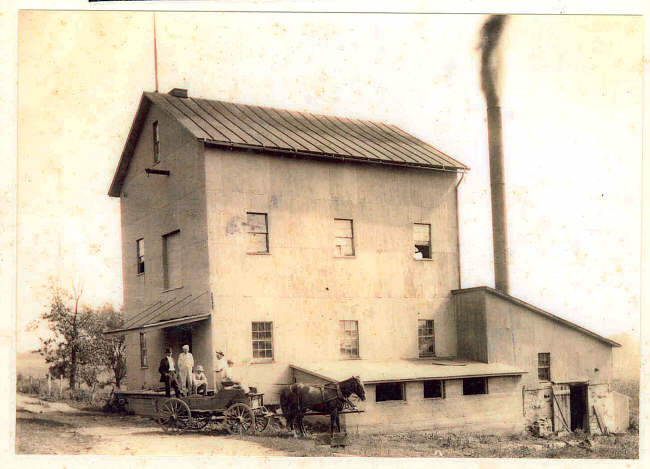

First mill on Gattermeir property The mill was originally known as the Buckeye Mill. They remodeled the frame building, put in new Buhrs, and in the summer of 1887, changed to the roller system, fitting in two double sets of 15-inch rollers. This a first class mill was operated until it was destroyed by fire in 1895.

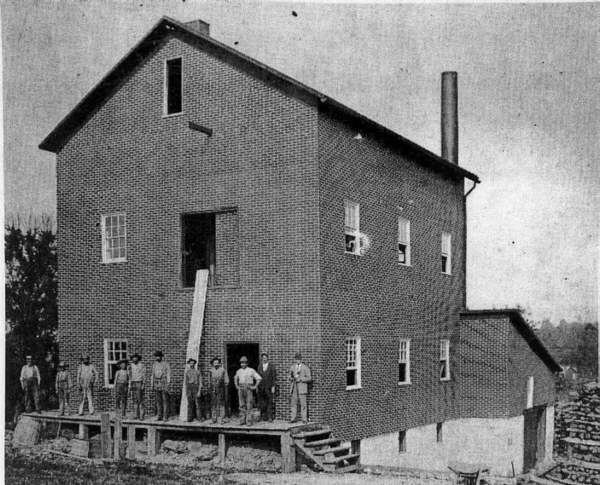

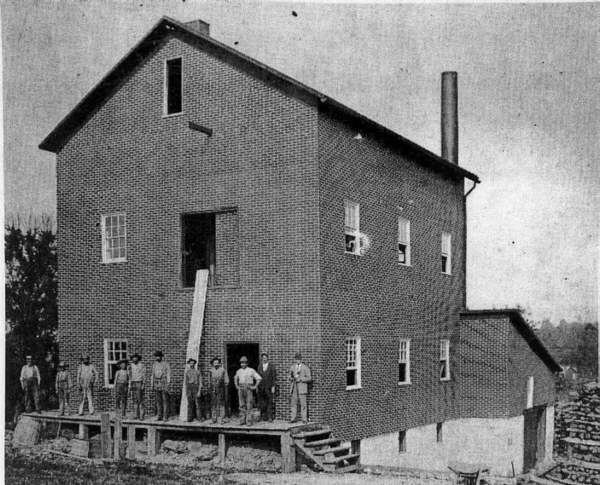

Second Gattermeir Mill 'New’ mill built near Olean in 1896 by Joseph Gattermeir and Joseph Goodman replaced the one destroyed by fire a year earlier. It was of metal siding, printed and painted to resemble brick. Twenty years later a tornado destroyed this mill. The senior Mr. Gattermeir is shown at the center of the picture. The youths pictured are his eldest sons Ben and Henry. All seven of his sons broke into the milling business as youths, serving as firemen feeding cordwood, shown stacked at right, for the steam engines. Only two, Almon and John, remained in the milling business at Olean.

Joseph Gattermeir went together with Joseph Goodmen and rebuilt on the same site and with the assistance of his sons, operated this mill until 1916 when it was totally destroyed by a tornado.

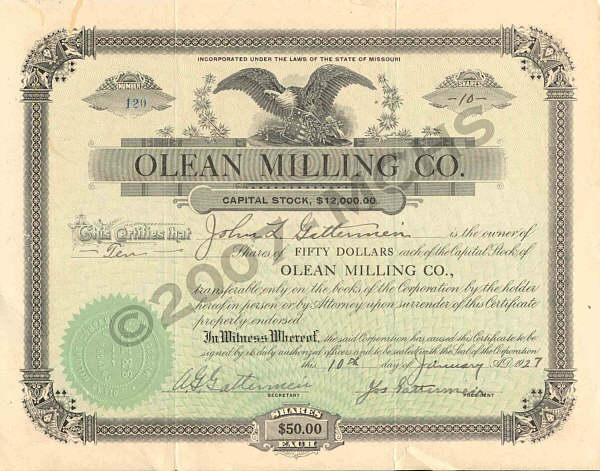

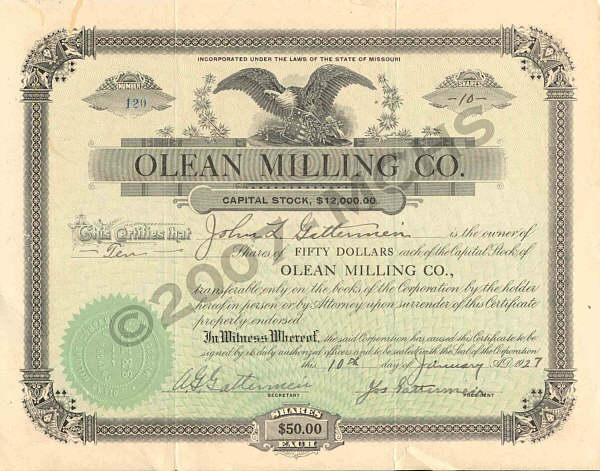

Mr. Gattermeir then organized the Olean Milling Company and rebuilt in Olean, across from the railroad Depot. Mr. Gattermeir was an industrious, energetic and hard working man and soon established a going business which continued under the able management of his sons. On December 13, 1928 he died at his home in Olean, having attained the age of 80 years, 10 months and 22 days.

Olean Mill - Stock Certificate In January 1970, the mill was purchased by six farmers, thus concluding 89 years of active participation by the Gattermeir family. They purchased the business from Olean Milling Co., whose president was John Gattermeir; vice-president and treasurer, Almon G. Gattermeir, and secretary, Mrs. Gladys Walker. The new corporate members were Don Bledsoe, Olean, president; Carl Atwell, Tuscumbia, vice-president; Paul Steele, Jr., (who came to Olean from Illinois to assume management of the mill) secretary; Edward Pettigrew, Latham, treasurer; and Raymond Helmig, Linn and Ed Holman, Richland.

Gattermeir Homestead The Gattermeir homestead still stands across the road from the first mill just outside Olean. Robert Gattermeir has built a home and barn across the road on the site of the old mill. He also built a guest house on the foundation of the old mill.

TUSCUMBIA MILLS

By Clyde Lee Jenkins

In 1865, Marks Lesem was proprietor of the Tuscumbia steam saw and grist mill, situated on the eastern side of town, in the crackerneck section.

In 1867, George Doolittle and N.C. Keyes erected a saw mill at Tuscumbia, situated where the pavilion now stands in Riverside Park.

Girard B. Allen stated, "I reside in St. Louis; am engaged in the foundry business. Sometime in December, 1866, I sold Doolittle and Keyes an engine, second hand boiler, saw and milling machinery."

"I reside in St. Louis," John Rohan said. "My occupation is that of boiler maker. I have been engated in the business about 18 years. Doolittle and Keyes ordered a two flue boiler, and afterwards changed it to a six flue boiler. I examined and repaired this six flue boiler."

"I know the boiler well," Rohan continued, "It was formerly on the Steamer Sioux City, then when the Steamer Admiral was built, this boiler was put upon her, and before the Admiral ever made a second trip, having run and returned from St. Louis to Cincinnati, she was sunk by ice in the harbor at St. Louis. This boiler was raised in a few weeks; Allen buying the boiler at public auction. The boiler was inspected by me. It was a first class, second hand boiler."

The boiler and machinery shipped from St. Louis to the Osage River by railroad, was carried upstream by steamboat to Tuscumbia. In February 1867, the boiler and machinery were put ashore at the County Seat.

Mr. Chalfant, an engineer having 22 years experience, installed the boiler and assembled the engine. "I have put up several engines," Chalfant said, "Having run all classes of high pressure engines. I put up the boiler in March, 1867. I examined it, even worked inside of it. Outward appearance looked well enough but there was a hole in the boiler which never had been filled. I fixed it with a fusible plug like used in steamboats.

"Doolittle knew nothing about machinery," Chalfant continued, "Keyes having some experience as a mechanic. I fired the boiler for them, got up 80 pounds of steam, and started the mill sawing, myself, on April 1, 1867," he concluded.

"We Run steadily for nine months," N.C. Keyes said, "Then slowed for want of demand on lumber and plan,."

Later a grist mill was added to the enterprise with J.H.G. Moss, a black man, the miller. Other employees at the mill included Willie Turpin and D.J. Welshons, with Almond C. Keyes running the furnace.

BEAR CREEK MILLS

In 1870, the Keyes brothers, Newel C. and Almond C., removed the saw and machinery from Tuscumbia to Bear Creek, installing a boiler and engine, doing an extensive business. On March 31, 1871, they sold the mill to John Hironimus, George Barnett, William H. Moyer, and Ira T. Johnson for $2,350. In July of the same year, John Hironimus purchased from Ira T. Johnson his one-fourth interest in the mill, for $1,000; then in 1872, John Hironimus, George Barnett, and Wm. H. Moyer sold the works to William Hauenstein for a sum of $2,200. This enterprise was successively known as Keyes Bro.'s Mill, Hironimus Mill, and the Bear Creek Mill.

SUGAR CREEK MILL

Mathias and Frances Leuthen operated a grist mill at the mouth of Sugar Creek, in the late 1860's and early 70's. They used the boiler on the Steamer Folly to drive the engine. In 1870 they added a saw to the enterprise.

On November 26, 1872, they sold the steam saw and grist mill, including one pair corn burrs, and all appurtenances belonging to the Steamer Folly, to William E. Lurton for $800.

ST. ELIZABETH MILL

In 1869, Owen Riggs set up a mill by the Osage River, and commenced sawing lumber for dwellings and the church in the river town of St. Elizabeth. On October 9, 1873, Riggs sold the saw mill, including boiler, engine and app appurtenances to John W. Medlin of Moniteau County for the sum of $1,300.

GOODMAN-BUCKEYE MILL

Joshua Goodman, born in Ohio in 1832, after his marriage on August 24, 1856, to Mary Elizabeth Immell, emigrated to Miller County, purchasing a partly improved farm of 300 acres in Saline Township.

Captain Goodman, in 1866, erected a steam grist mill northeast of present day Olean. The place was immediately styled the Goodman Mill. In 1871, having made some improvements, and with P. Myers as a partner in the enterprise, the firm was styled the Buckeye Mill, serving patrons in Miller, Moniteau and Cole counties. Goodman and Myers with A. Pitchford operated the mill until 1881; the firm was sold to Joseph Gattermeir and Zwanzig brothers.

GLAZE CREEK MILLS

Following the Civil War, Hugh Snelling operated the grist mill erected in the 1850's by Scott Strong and William Salsman, on the Wet Glaze Creek, doing an extensive business.

On February 15, 1868, Hugh Snelling and William Pope agreed, each furnishing one-half of the expenses, to erect a saw by the grist mill; running the saw one-half of each day and one-half of each night, the grist mill running when the saw was idle.

Immediately installing the machinery, the saw, when completed in 12 hours running time, easily turned out 400 to 500 feet of lumber and plan, Snelling and Pope then agreed, in writing, repairs to the mill dam would be shared equally.

In September 1868, Hugh Snelling sold his one-half interest in the saw to Levi W. Albertson; also, one-half of his interest in the grist mill; the firm styled thereafter, Snelling, Albertson, & Pope.

The mill dam on the Auglaize Creek was situated where the waters rushed with great velocity, and fell with much force. "The stream is very rapid at the dam," Snelling said, "The fall is about five and one-half feet per mile. The dam is 16 or 17 years old, constructed of stone and timber."

In 1869," Snelling continued, "Pope came to me and named that he was about to sell to Albertson his interest in the saw for $1,400, and I replied, all right. The next day, on February 19, Albertson took complete possession of the saw, but as soon as put in possession Albertson would not do what Pope had done in keeping the dam repaired."

"When Albertson went into possession the dam was 5 1/2 feet high," Snelling said, "Then a rise in Glaize Creek reduced the height to less than 4 feet. I worked 42 1/2 days repairing the dam, spending over $300 boarding men and teams, furnishing powder, fuse, materials, and labor. The dam was in a critical condition when Albertson took possession; the reservoir filled with gravel to the spill-over."

"When I asked Albertson, "Snelling continued, "To pay his part for having the dam repaired, he would not do it, saying he had no contract. When I asked Pope to honor his written agreement, he would not do it, saying Albertson was the sole owner, that it was his obligation."

Snelling, Albertson and Pope, each suing the other over various rights and breaches of contract, continued litigation until the issues were finally resolved by the Supreme Court of Missouri.

GOLDEN'S MILL

L.W. Albertson operated a mill in Osage Township for three years, from 1866 to 1869, before moving to the Glaze Creek. Nearby, to the south and slightly east on the Big Tavern Creek, John C. Barr and Joseph Golden were partners, having commenced in the late 1850's, keeping a store and grinding grist.

On August 12, 1862, the partnership was dissolved by mutual consent; Golden remaining in the mercantile and milling business, John C. Barr becoming owner of the Steamboat Little Jack. Golden then installed carding machinery; doing a thriving business throughout the Civil War.

Alexander and William Wilson, Lafayette Crane and Allen P. Griffin worked at the place; the enterprise running day and night. Wood haulers for the furnace were paid with meal; bread stuff at that time of much greater importance than money.

In 1865, Everett W. Golden becoming proprietor of the store, mill and carding machinery, immediately added a distillery to the enterprise, making an abundance of good corn whiskey which was shipped in barrels to St. Louis by steamboat from Capps' Landing.

In 1868, to handle the many customers patronizing the place, Randolph Abbett opened a dram shop at the mill.

HARBISON MILL

After the beginning of the Civil War, William H. Harbison commenced running the old Johnston grist mill at the Big Spring where the Tuscumbia-California road crossed the Big Saline Creek. He added a distillery, and throughout the Civil War and afterward, operated the mill until the land came into possession of William H. Russell.

SLAWSON'S MILL

From 1866 to 1869, Joseph Slawson was a storekeeper and miller by the Big Tavern Creek, due east of Iberia. The enterprise consisted of a log dwelling, a double-room log storehouse with breezeway between, and a good mill. In 1868, the cash capital of the store was $1,400, making it a rather large enterprise. Mr. Ashworth helped Slawson with the storekeeping.

CAPPS MILL

Jacob Capps & Company operated a mill before and during the Civil War near the mouth of Humphrey's Creek. The mill was situated on the eastern side of the stream by the cemetery. A steam grist mill, a carding machine, and a distillery completed the enterprise.

John Curry was a merchant at the place as early as 1859. Also Jacob, Silas and Benjamin Capps engaged in flat-boating upon the Osage River.

In 1863 Jacob Capps, becoming proprietor of a ferry boat at the crossing of the State Road from Jefferson City to Iberia at the Capp's Landing, commenced moving the company's stands and equipment to the western side of Humphrey's Creek.

In the decade of the 1870's, other mills running in Miller County included Jesse Ratcliff's on the South Moreau Creek; Cook's mill on the Little Gravois Creek; Hoff's and Spalding's mill west of Spring Garden; Matthew's mill on the Saline Creek; and Thomas E. James' mill at Mint Spring. There was also a distillery at the Fishburn Spring in Franklin township.

In 1869, Charles E. Adams was proprietor of a carding machine situated on the Barren Fork, one-half mile south from the mouth of Whittle Creek; and John W. Coxen was operating a carding machine on big Bear Creek at later day Blackmer. Humes carding machine was running at Pleasant Mount.

MILLER COUNTY MILLS

By Clyde Lee Jenkins

Early industry in Miller County included Thomas Sarter's grist mill, and Brockman's saw mill on the Saline creek in 1837; followed by William Bennight's grist mill, Loveall's grist mill, Johnston's grist mill, William Brockman's grist mill, William Matthew's grist mill, and Robertson Roberts sawmill b or near the same stream before 1850.

Bilyeu's grist mill, and West and Blyze's grist mill were early enterprises on the Big Tavern Creek followed by Branham's mill, Stephen's mill, Bray's mill, Golden's mill, and Slawson's mill before the Civil War. Pack's mill was situated by a big spring on Humphrey's Creek as early as 1845.

Brockman's saw mill on the Grand Auglaize included Johnston's, Sarter's, Bowlin's, Foxes, Coxen's, Scaggs' and Salsman's.

Bowlin's mill was located south of present day Kaiser, on the Grand Auglaize Creek, Benjamin Franklin Bowlin, proprietor. He was the 10th son of an Irish father and German mother who arrived in Virginia about 1780, later moving into Tennessee and Kentucky.

Benjamin was born April 22, 1808, in Barren County, Kentucky, and when of age, married Sophia Jane Dodd of Tennessee. Shortly after marriage they migrated into north Missouri, but being "hill folk", soon removed from the place to Auglaize Creek in Miller County where wild game, water, and timber were in abundance.

Benjamin erected a two story puncheon log house, building a mill for the grinding of grain, suing water from the Wet Auglaize Creek for driving the milling machinery.

SALSMAN'S MILLS

On October 16, 1854, Scott Strong and William Salsman petitioned the Miller Circuit Court for a writ of ad quod damnum, and being granted, under seal of the Court, was issued to the Sheriff of Miller County.

Having declared themselves the legal owners of a certain tract of land, being the E 1/2 of the SE 1/4 of Section 26, township 39 N, Range 15 W, traversed by a water course known as the Wet Glaize, they proposed placing an earthen fill across the stream seven feet in height for operating a grist mill, running two set of burrs, and a saw mill, running one saw.

Sovereign Popplewell, the legal owner of a farm adjoining the proposed mill-dam site, informed the Court that blocking of the water course would inundate a reasonable portion of his farm, damaging the land, his garden, orchard, out-buildings, and mansion house, generally endangering the health of himself, his family, and the entire neighborhood.

To inquire into the matter, as required by law, the Sheriff empanelled a jury of twelve men-Tolbird Bass, Daniel Etter, G. Robinson, Joseph Golden, John Graham, Cyrus Vandensen, A.T. Wilson, G. Breedlove, Wm. Kuykendall, William DeGraffenreid, James Waddle, and George Robinett.

Meeting at the site, after hearing every question, the jury reported:

"We the jury agree and say, First: What damages each proprietor will sustain by reason of inundation consequent upon the erection of this dam as proposed? We the jury say none. Second: Whether the mansion house of any such proprietor or the out-houses, curtilages or gardens thereto immediately belonging or orchard will be overflowed thereby? We the jury say not. Third: Whether and to what extent navigation ordinary and fish of passage will be obstructed by such erection and whether and by what means the same may be prevented or dismissed? Damages none. And Fourth: Whether the health of the neighborhood will be materially annoyed in consequence of such erection? We say none."

Erecting the dam and raising a mill house, Scott Strong and William Salsman installed milling machinery, later adding a saw, doing an extensive grist and lumber business before the Civil War. William Salsman also purchased John Johnston's grist mill in Camden County, with Marcus L. Halstead joining the enterprise as a partner in 1856.

RATCLIFF'S MILLS

In February, 1855, Jesse Ratcliffe petitioned the Miller Circuit Court for a writ of ad quod damnum, which was granted under seal of the Court, and issued to the Sheriff of Miller County.

Ratcliffe's petition declared himself the legal owner of a certain tract of land situated in Miller County, purchased by him from the United States, described more particularly as the N 1/4 of lot 2 of SW 1/4 Section of Section 7, Township 42 N., Range 15 W, through which a water course passed at or near the Southeast corner, known as the South Moreau Creek.

Ratcliffe proposed erecting a dam seven feet and six inches in height across this creek to run a grist and saw mill, the houses and machinery to be erected on the easterly side of the stream. John Comes, a residen of Morgan County, bening the owner of the land on the westerly side of the stream, made action by the Court necessary in order for him to attach his dam upon it.

Twelve disinterested persons, summoned, sworn by the Sheriff, and empanelled as a jury, met at the proposed site on April 8, 1856, inquiring upon the matters touched by the petition. Afterward, Ratcliff's mills commenced running and continued in operation many years.

JOHN HUMES AND COMPANY

On March 11, 1857, John Humes of Pleasant Mount, entered into a co-partnership agreement of five years' duration with Daniel Cummings and Emanuel Goodlove of Tuscumbia, for the purpose of erecting a steam saw and grist mill, and such other buildings and machinery as they deemed expedient, under the name and style of John Humes and Company.

The agreement stated, "John Humes shall devote his undivided time and attention to the business of the concern, erecting the necessary buildings, operating the machinery with Emanuel Goodlove and Daniel Cummings, each furnishing one hand."

A carding machine house of three stories, the tallest building in Miller County, was erected at Pleasant Mount, and a manufacturing complex, including a saw and grist mill, constructed at Tuscumbia.

John Humes having erected, and successfully operated the first grist mill run by steam power in the county, was a capable engineer and an experienced mechanic. His grist mill engine at Pleasant Mount, first running in 1853, was now driving carding machinery.

Upon completion of the company's enterprises, John Humes sold his undivided third part of the steam saw and grist mill at Tuscumbia, including the engine, boiler, Machinery, timbers, teams, wagons, wheels, ways and appurtenances to Daniel Cummings and Emanuel Goodlove. In turn, Cummings and Goodlove sold to Humes their interests in the carding machine house at Pleasant Mount.

Before the Civil War, Cummings & Goodlove at Tuscumbia, Humes and Alcorn at Pleasant Mount, were unable to keep abreast for want of time, with the grinding of their customers' wheat and corn; the carding machinery at Pleasant Mount running day and night in season.

In this era, the making of clothing was completely performed in the homes, with wool and cotton made into yarn or thread by means of the common hand cards and spinning wheels, then woven into cloth with nimble fingers rapidly twisting and manipulating knitting needles or woofed and warped upon hand looms.

The carding machines, run by steam or water power, gave an impetus to this work by carding hanks of raw wool with speed and precision, lightening the work of many women, and making home life for them more enjoyable, if only a little so.

At the beginning of the Civil War, carding machines were running at Pleasant Mount, Golden's mill in Osage Township, and at Silas Capps' mill near Capps' Landing by the Osage River.

Distilleries were usually associated with the milling enterprises, making snake-bite medicine of good quality, and in quantity.

|

|