|

Monday, November 28, 2011

Progress Notes

Among the things which helped Miller County’s development early on was the abundant resource of water. Steamboats traversing the Osage River at one time were the only means by which needed goods and products could arrive here or be transported away from here because we had no decent roads. The many springs found in our county fed the creeks which in many instances flowed the year round providing water for livestock and wildlife.

In Clyde Lee Jenkins’ History of Miller County VII p. 20 Clyde writes:

“The streams were filled with many kinds of fish. In 1835, Pinkney S. Miller, then only eight years of age, caught a fish weighing over 120 pounds. He was fishing in the Saline Creek due south from Pleasant Mount. Pinkney’s father being nearby, upon hearing his young son’s cries for help, rushed to his side, and together they landed the monster. William Miller and another man carried the fish home by thrusting a pole through its gills, shouldering the pole. The tail of the fish, even though both men were over six feet tall, dragged the ground. Also, about this time, two young men named Etter and Bilyeu, fishing in the Wet Auglaize near the line of later day Kinderhook (Camden) County, caught a catfish of such great size they used oxen to haul it home. They lashed the fish upon two poles, using leather thongs, making a pole skid which was dragged over the ground by a yoke of oxen to the log cabin of Daniel Boone Etter.”

The running creek water was harnessed to power mills throughout the county such as the ones at Brays mill near Iberia and the Wright mill on the Little Saline creek north of Tuscumbia (photos 01 and 02).

01 Brays Mill

02 Wright's Mil

The first mill in the county to be run by water power was built on Saline creek by William Brockman probably in the 1840’s.

It wasn’t long before steam power was introduced to the county. In 1853 John Holmes built the first mill to be run by steam power near Pleasant Mount. Steam power was well known by 1853 but was late in coming here probably due to the abundant running streams which sufficed for running small local mills.

According to Wikipedia the idea of using boiling water to produce mechanical motion has a long history, going back about 2,000 years. Early devices were not practical power producers, but more advanced designs producing usable power became a major source of mechanical power over the last 300 years.

For many years steam power was the only source of mechanical energy available being used to propel the large steamboats up and down the Osage River, the J.R. Wells being our most well known (photo 03).

03 Steamer J.R. Wells at Anchor

But perhaps the most common use of steam power in our county came with the introduction of threshing machines.

According to Wikipedia:

“Early threshing machines were hand-fed and horse-powered. They were small by today's standards and were about the size of an upright piano. Later machines were steam powered, driven by a portable engine or traction engine. In 1834, John Avery and Hiram Abial Pitts devised significant improvements to a machine that automatically threshed and separated grain from chaff, freeing farmers from a slow and laborious process.”

I’m not sure when the first steam powered threshing machine was used here. One of the earliest owners of one was John West of Maries County who often came to Miller County during harvest time. Here is a photo of his machine (photo 04).

04 West's Steam Engine

The photo was sent us by a descendent of John, Richard West. Here is what he wrote:

“The photo of the steam engine was in my Grandfather Oscar West’s possession. On the other end of the belt drive is a wooden sided threshing machine. During those simpler times the grain was bagged by the bushel without being weighed; you were trusted to put what looked like the right amount in each bag. This work was done without any amenities for job comfort which made it dirty and exhausting. It was enough of a novelty to attract a photographer and a group of spectators in the background. In the context of the early twentieth century, this was their modern technology, which to them was probably amazing.

The nearest my Uncle Arvel and I can figure is that Oscar is on the steam engine. He had the job of keeping a fire in the boiler. His father, John, is standing in front to give the signal to begin feeding the grain. My uncle remembers my Grandpa and Great Grandpa talking about the toils of operating the engine. It had no brakes. To control its speed going down a steep hill required a wooden fence post shoved into the spokes on one of the large rear wheels. My Dad remembered the bearings on the equipment had oil cups. When one of the cups ran out of oil it would smoke and nearly catch fire.”

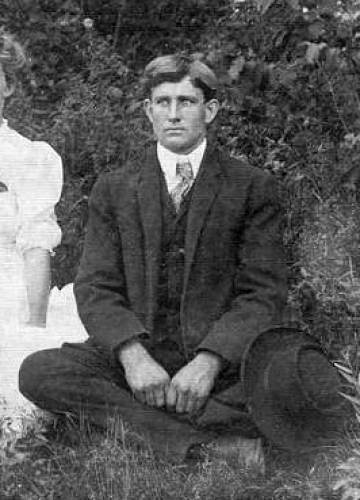

Charlie Bill Abbott, former sheriff of Miller County, owned a steam powered threshing machine for several years during the early 1900’s (photo 05).

05 Charlie Bill Abbott

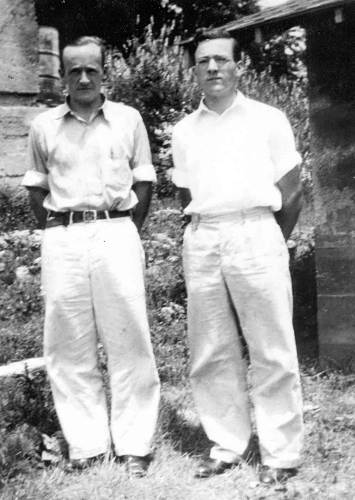

About fifteen years ago my uncle David Bear, in a conversation with his brother Arthur Bear (photo 06), recounted his memories of Charlie Bill coming to the Bear farm (located on Dog Creek a couple miles east of Highway 17).

06 Arthur and David Bear

This was taken from a previous Progress Notes:

“I saw my first car when I was four or five years old. One of the earliest machines I remember seeing was a wheat threshing machine pulled and operated by a large steam boiler. Charlie (Bill) Abbott owned the equipment. He would go from farm to farm traveling at a speed of about two miles per hour. It would enter the field and set up at a spot picked by Charlie. The thresher had two components: the boiler and the separator. On the road the separator was towed by the boiler, but in the field, the position of the two changed. The separator was then connected to the boiler by a huge belt which transferred the power from the boiler to the separator. The fuel for the boiler was wood which had been previously cut someplace nearby. Prior to the arrival of the thresher, the wheat had been cut with a wheat binder. The binder also tied the wheat stalks into small bundles (about an armload) and dropped them on the ground. These bundles were then gathered and put in shocks to dry. When the threshing machine came a few weeks later, several farmers in wagons with hay frames on them would load up the bundles of wheat and haul them to the threshing machine. At the machine, the wheat bundles were tossed into the separator by someone using a pitchfork. The separator had a string cutter to cut the binder twine before the wheat went in to the separator. As the bundles of wheat went through the separator, the grain would come out in a chute at the bottom where someone would be holding a sack to catch it. The blower blew the straw and chaff into a big stack. It was blown through a metal pipe about eight inches in diameter. A large number of people was required to perform all the jobs of threshing. These were hard working days for the farmers and it usually came on a very hot day. It was a great day for small kids. I was too young to work, so I watched in awe. The women always had a tremendous spread of food. Mom and the neighborhood women had many kinds of meat, pies, cakes, canned fruit, pickles and many other items. These great banquets will be in my memory as long as I live.”

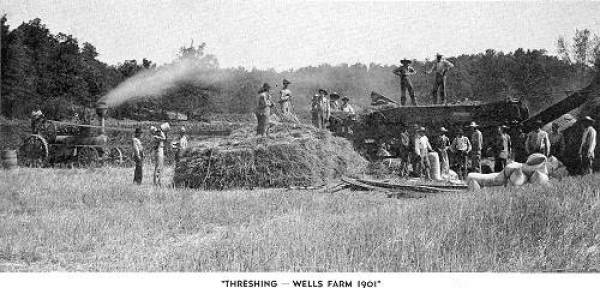

I’m not sure but the following photo of a steam engine tractor and threshing machine at the Wells farm may have belonged to Charlie Bill Abbott (photo 06a).

06a Threshing Machine at Wells Farm - 1901

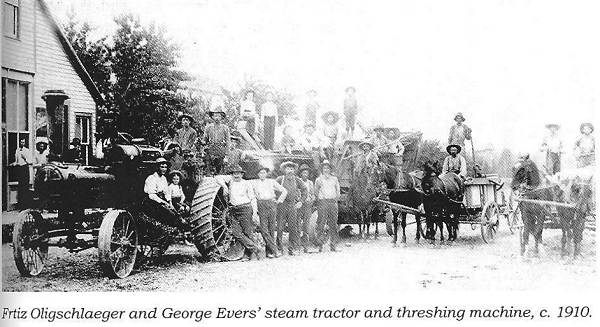

I also have a photo of the first steam powered tractor and thresher which was located at St. Elizabeth (photo 06b).

06b First Steam Tractor and Thresher of St. Elizabeth

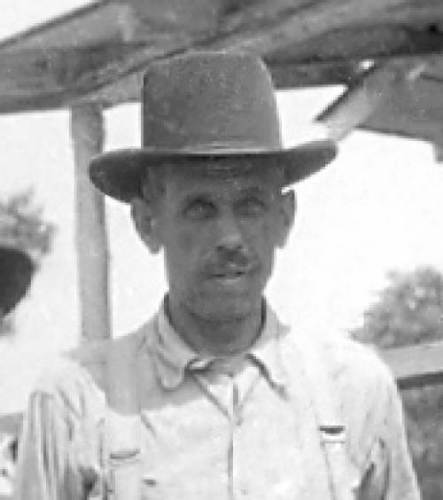

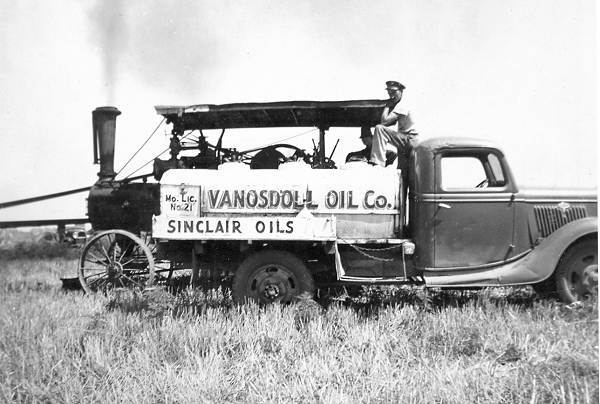

Another Miller County resident who used steam powered equipment early on was Clark Vanosdoll of Eldon (photo 07).

07 Clark Vanosdoll

The following is copied from a previous Progress Notes:

“At age 21 Clark opened a small well drill business. In fact, he had the first steam engine used for well drilling used in the area (photo 08).

08 Vanosdoll - First Steam Engine used for Well Drilling

Until then common practice had been to hand dig wells and then shore up the walls with rock. Vanosdoll’s new drill could drill a well with only a six inch diameter. The hand pump or gasoline powered pump would soon replace the bucket and rope for getting water to ground level.

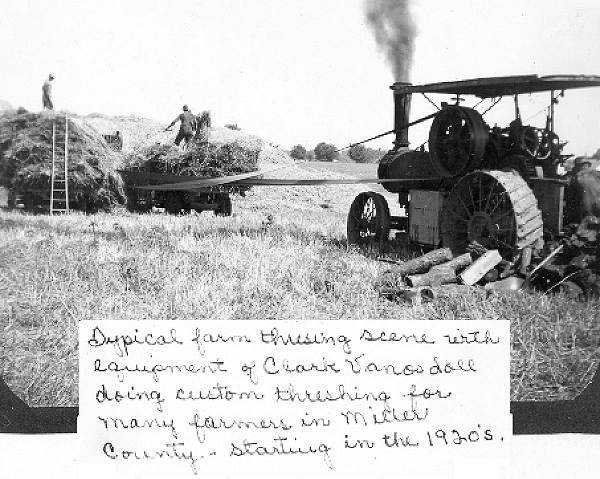

Later on Clark purchased a steam powered thresher and worked from farm to farm. Helen Phillips remembers the thresher and remarks that Clark was always proud that his forty acres outside town usually brought in a bigger harvest than many of the farmers’ crops.

Note: Here are photos of Clark’s steam engine and threshing machines (photos 09 - 13):

09 Vanosdoll - Steam Engine and Thresher

10 Vanosdoll - Threshing Machine

11 Vanosdoll - Steam Tractor and Oil Truck

12 Vanosdoll - Steam Powered Engine

13 Vanosdoll - Thresher

Clark also was a promoter of better roads, serving for 42 years as district road commissioner. He obtained the contract from the state to supply gravel for the new Highway 54 coming south from Jefferson City. According to John Vanosdoll, Clark’s grandson, although Clark neither drank nor smoke, the day he entertained the state officials to convince them to give him the contract for the gravel for the road the “smoke was thick and whiskey was flowing.” Clark also convinced the state to bring the road to Eldon rather than take a southerly route through Eugene and Tuscumbia.

Here is a photo of his Aultman Taylor steam engine road grader (photo 14).”

14 Vanosdoll - Steam Powered Road Grader

Another Miller Countian who used steam to power a well drill was William Spencer who lived near Eugene (photo 15).

15 William and Maggie Crane Spencer

The following information was given me by Gene Spencer, son of William:

“Growing up, Gene, in addition to his routine farm chores, also helped his father, William, in a well drilling business. Gene said originally, his father used a team of horses which walked a circle turning a drill bit to dig the wells. Although this was a faster and deeper method than the hand dug well, it still was quite primitive by today’s standards. Later, his father bought a steam engine which turned a wheel that mechanically oscillated a lever which caused the drill bit to go up and down vertically. The bit had to be heated over a forge and sharpened four to five times daily. Later a gasoline engine replaced the steam engine, and finally, an integrated system was designed wherein the drill was raised up and down by a PTO run off a truck.”

You can read more about the Spencer family at this preview Progress Notes.

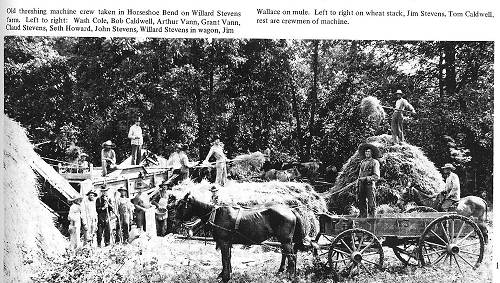

Here is another photo of a steam tractor and thresher over in the Horseshoe Bend area. One of those pictured is Grant Van, grandfather of Dick Dolby of Eldon (photo 15a).

15a Steam Engine and Thresher at Horseshoe Bend

Click image for larger view

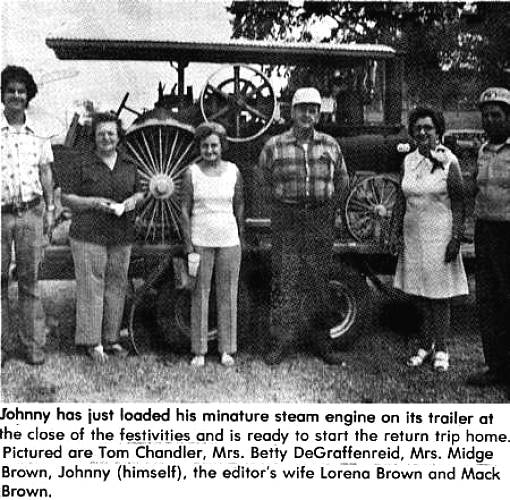

Steam engine powered devices have continued to capture the imagination of people today, especially the old threshing machines. One of the well known steam powered threshing machine enthusiasts of our county is Johnny DeGraffenreid (photo 16).

16 Johnny DeGraffenreid Steam Engine

In next week’s Progress Notes I will feature Johnny and the Miller County DeGraffenreid history.

That’s all for this week.

Joe Pryor

Previous article links are in a dropdown menu at the top of all of the pages.

|