|

Monday, November 24, 2008

Progress Notes

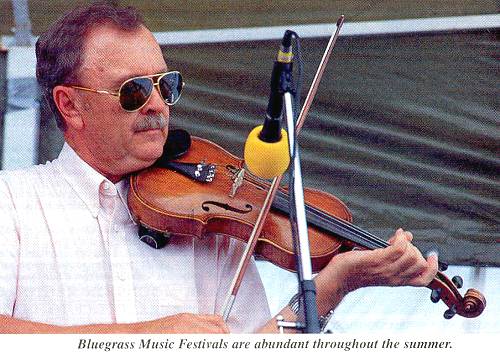

Last week one of the people featured was Eldon fiddler, Clifford Hill (photo 01):

01 Clifford Hill playing at a Bluegrass Festival

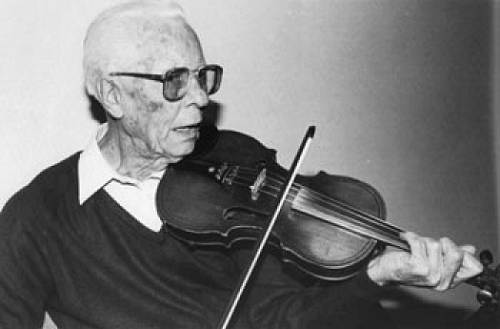

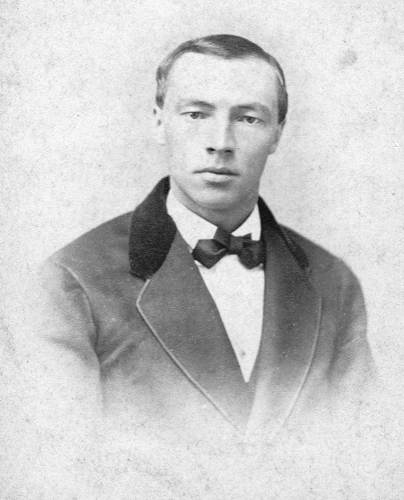

Clifford told me that he thought the best fiddler he ever heard was Lyman Enloe who was born and raised half way between Eldon and Jefferson City (photo 02).

02 Lyman Enloe

The Enloe family is a well known family of north Miller County and southern Cole County with long time roots here. Quite a few of them have been musicians. Because of Clifford’s admiration of Lyman, as well as others to whom I have talked who heard him play the fiddle, I thought I would feature him this week as part of an intermittent series of biographies of Miller County fiddlers. In addition to Clifford Hill, I already have featured another well known Miller County fiddler, Jimmy Skiles, on the Progress Notes of July 13, 2007.

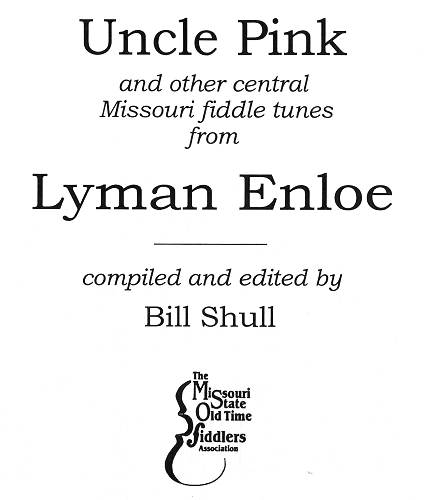

Much of the information about Lyman, who passed away in 1998, came from a book Clifford Hill loaned me entitled “Uncle Pink” by Bill Shull (photo 03).

03 Uncle Pink

Uncle Pink was the nick name of one of Lyman’s uncles, Pinkney Enloe. Copied below from the book is Bill Shull’s introduction:

Lyman Enloe’s music is significant for two reasons. First, a good part of his repertory was acquired in the early 1900’s from much older fiddlers who transmitted to him the traditions of mid nineteenth century dance fiddling in central Missouri. Second, Lyman is a naturally accomplished fiddler and has an instinctive sense for the melodic structure of a fiddle tune. He thus is able to convey what was taught to him many years ago in a form that preserves the best aspect of the tunes.

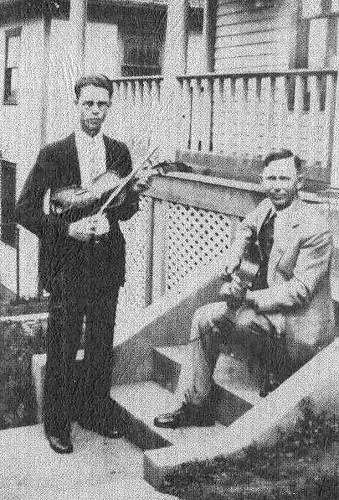

Lyman’s repertory was accumulated during three separate periods in his life. The earliest tunes were learned in his pre teens and teens from his family and their friends (photo 04).

04 Lyman Enloe and Father

He garnered a whole new “tune list’ when he moved to the Kansas City area around 1948. Then, in the 1960’s, he gravitated to bluegrass and became fluent in that style of fiddling.

Lyman’s repertory included tunes varied in key, structure, meter, and tuning. Some of the tunes have Lyman’s distinctive imprint on them, but most are close copies of what Lyman heard shortly after the turn of the twentieth century in family get togethers, dances, and fiddle contests. Lyman usually varied the melody and bowing subtly every time he repeated a part, making his playing more interesting to hear.

Bill Shull

July, 1993

Bill also wrote a longer biography about Lyman which I will copy here:

Lyman Enloe was born March 15, 1906, in Cole County about halfway between Jefferson City and Eldon, Missouri, in a region known geographically as the Upper Ozarks. He was one of two children of Elijah and Jane Enloe and had several half brothers and sisters.

Lyman’s dad was a fiddler, and Lyman says that his dad was one of the best fiddlers in the part of the country where he grew up. At that time, transportation was by horse, or horse and buggy, and nobody got far enough away from home to establish a real reputation. But according to Lyman, his dad had “a real smooth bow arm and long fingers,” and could easily best most of the local fiddlers. Lyman’s dad learned his repertory from the fiddlers around Cole and Miller counties in the late 1800’s. In particular, Lyman remembers his dad mentioning Ben Hines and a fiddler by the name of “Gum” Messerschmitt. Lyman’s half brother, Wade Enloe was also an active fiddler.

Lyman’s dad would sit around evenings during the week and every Sunday afternoon and play fiddle. Lyman’s sister played banjo and his half brother played bass. With Lyman on guitar, Elijah had a full band. Lyman remembers the large gatherings of people, and wishing sometimes he could be outside playing with the other kids instead of inside with the old folks picking a backup on the guitar.

Tony Gilmore of Jefferson City was Lyman’s most important early influence. Gilmore, a railroad freight conductor by occupation, was among the fiddlers who performed regularly over state owned radio station WOS, which broadcast from the dome of the Capitol from 1923 to 1933. Lyman played the guitar for Gilmore and other fiddlers for several years before attempting the fiddle. Lyman’s dad had made a fiddle for him, but he had never played it and had it hanging on a wall. When he was twenty two years old and married, he was sitting home one day looking at the fiddle, and decided to take it down and try it out. Within one year he had a regular radio date playing fiddle over WOS. From his years of playing backup for his dad and his uncle Pinkney “Pink” Enloe, he had memorized many melodies, and only needed to fit them to his fiddle. Lyman also knew many of Gilmore’s tunes, and had also learned a number of pieces from Lee Carpenter of Eldon, Missouri. On Lee’s first visit to the Enloe home, a group of guests sat palavering while Lee nervously paced around. Lee finally said “Well boys, you know what we come here for, let’s get after it” and pulled his fiddle out and started playing. This led to many other visits and many shared tunes.

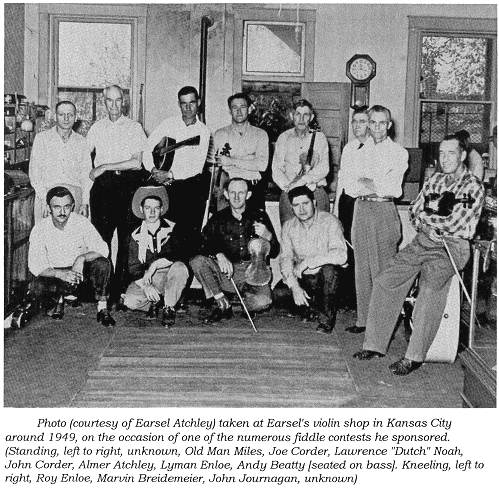

Lyman moved to the Kansas City area around 1948 and began assimilating a whole new repertory of tunes. He participated in the jam sessions and contests at Earl Atchley’s violin repair shop, and continued to play for dances and at contests (photo 05).

05 Earl's Music Store

Click image for larger view

At one point Lyman put his music aside for nearly twenty years; however, in the late 1960’s he became friends with a group of Kansas City area bluegrass players. His style of playing fit well with this group and after a number of successful engagements the Bluegrass Association was formed.

The Bluegrass Association consisted of Lyman on fiddle, Chuck Steadman on mandolin, Jim McGreevy on banjo, Don Montgomery on bass, and John Bennett on rhythm guitar. The group played together for thirteen years and cut four albums. Personal commitments eventually caused the Association to disband. Veterans of the bluegrass festival circuit still regard them as one of the outstanding Bluegrass groups to come out of Missouri.

Lyman won the Society for the Preservation of Bluegrass Music in America (SPGMA) awards for six years running (1983 through 1988) in the category of “old time fiddler,” an accomplishment not equaled by any other fiddler. He also won the prestigious Nashville SPGMA National convention “Old Time Fiddler” award on two occasions. Lyman passed away in 1998 in Lee’s Summit, Missouri where he had a house painting business.

If you would like to listen to Lyman play his fiddle, the website listed below has three of his fiddle tunes available for you to hear; just click on the play button for each tune and you can hear some of Lyman’s recorded music. This website also has additional biographical information about Lyman:

http://fiddle.missouri.org/people/profile/?person=10

I will be featuring other Miller County fiddlers from time to time in future Progress Notes.

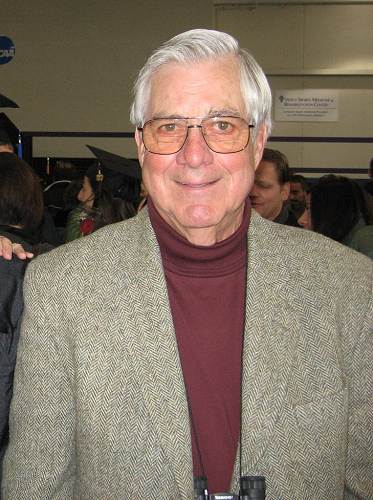

Last week I placed a series of photographs telling a pictorial story about the traditional custom in the Ozarks of the fall butchering time given me by Pat Wallace Hill. The photos inspired Elmer (Dub) Brown (photo 06), who was born and raised in the Ginger Ridge area between Tuscumbia and Eldon, to send me this essay about his own memories of old time fall butchering on the farm:

06 Elmer Brown

BUTCHERING

We pretty much practiced what is known today as subsistence farming. That is, you raise as much of your own food as you can. Whatever is left over is sold or bartered for those things you don’t raise. This extended to our pork and chickens.

Mother always bought two pigs in the spring or early summer to be raised to provide meat. They were usually just at the weaning stage and would weigh about 40 pounds each. By the time butchering time arrived they would be about 225 to 250 pounds.

Butchering time was usually in late fall or early winter to take advantage of the cold temperatures so the meat would not spoil. No one had refrigeration and it was stored in smoke houses or whatever shelter you happened to have.

Typically two or three neighbor men got together to do the job. Since there wasn’t a man at our house, mother sometimes paid a couple of people to do ours. Often though the barter rule came into play. We had the only scalding vat and block-and-tackle, referred to by one of our neighbors as “block-and-tickle” in the community. They were always available for loan but every once in a while Agnes would call in a marker and let it be known that in exchange for their use her hogs should be done for free.

The scalding vat was the only one of its kind in the neighborhood and made the job of getting the hair off the carcass a lot easier than the traditional method using a 50-gallon barrel. It had been constructed by my brother, Bert some years before. Wide planks formed the sides and ends with galvanized sheet metal fastened along one edge to form the bottom. A trench was dug with one end open and the other feeding into a short piece of stove pipe to create a draft. The vat was placed over the trench, filled about half full of water and a wood fire built underneath to heat it. I can still remember that it seemed to take a huge amount of water that had to be carried from the house and I’m sure I complained every step of the way.

When you had a group who had worked together before there were usually certain skills attributed to each one and he took great pride in doing that particular task and doing it well.

Since we did not have the sophisticated handling equipment available to the meat packers we had to improvise to some extent. In the packinghouses the animals are stunned by a blow to the forehead or an electric shock, hoisted to an overhead conveyor by a shackle around one hind leg and their throats are quickly cut so they will bleed quickly and completely. This is all done with a minimum of commotion so as to not get the animal too excited. We understood and practiced that same concept but since we lacked the hoisting and conveying equipment, had to improvise. The pigs were corralled in a small pen and one of the crew, usually the owner, fired a .22 into the forehead at the intersection of lines imagined diagonally between the ears and eyes. When the animal dropped, which it did immediately if the aim was true, one person would quickly cut the throat so as to sever the jugular vein.

The carcass was then dragged to the platform next to the scalding vat. This was usually the barn door that had been taken down for the day and laid across a couple of logs. The carcass was stretched across two chains, which were then crossed over the top. With one or two strong men on each end of the chains, it could be rolled gently into the vat and where it could be rolled to make sure that all sides were exposed to the hot water. This loosened the hair and made it easier to remove. If the water was either too hot or too cool the follicles would not release and you ended up having to shave the carcass. This was not a pleasant task since butcher knives were the only tools available to serve as razors. No one had a thermometer so various ones would swipe a finger through the water and then have a discussion on whether it was the right temperature. Achieving consensus sometimes took several minutes since no one wanted to be too assertive for fear of giving offense or being wrong and creating extra work for everyone.

Once the carcass was scraped it was moved to the hoisting area, usually a nearby tree, where it was hung head down by aid of the block and tackle and a single tree from a horse drawn farm implement between the hind legs as a gambrel stick. The next step was the removal of the entrails. The head would then be removed and set aside for further processing. The final step was to split the carcass down the spine using an ax and whatever type of saw was available. These were later cut into hams, shoulders, sides for bacon, etc.

Butchering day itself was only the beginning of the work. Now came the tedious, time consuming and often-unpleasant tasks of turning the raw material into usable products.

The hams and shoulders had to be trimmed just so and the heads had to be skinned and any usable meat cut off. Mother never trusted anyone else to perform these tasks and as I look back I can’t say that I clamored to be a part of it. Part of these scraps would be made into sausage but mother always set aside a certain amount for the mincemeat. Those rich, mincemeat pies were among my favorites. When I was in college, there was often a package of mincemeat cookies included in my laundry when it was returned to me each week. My roommates soon caught on and always seemed to be on hand when I opened my laundry box.

The fat was cut off and cooked in a large pot to separate it from the tissue. If the weather was decent, this would be done in a large kettle over an open fire out in the yard. As is often the case however, Mother Nature did not cooperate so it would be done in the house. The smell of rendering lard is not pleasant and it seemed to linger in the house for days but we accepted it as a fact of life. The finished product was always packed in quart or half-gallon jars and stored in the cellar, which was cool and kept it from becoming rancid.

The exposed flesh on the hams, shoulders and bacon were immediately coated with salt to act as a preservative and drying agent. They were then hung by wires from the rafters of the smokehouse to keep mice and rats from getting at them. After several weeks mother would rinse off the plain salt and coat the meat with Morton’s Sugar Cure and re-hang them. They were then ready for smoking.

By the time I was about 10 my job was to procure the wood. We had an abundance of young hickory trees nearby so there was never any problem with supply. Trunks and limbs would be cut into short, lengths and we would build a small, smoldering fire immediately under the hanging meat and keep it going for several days. I tended to operate under the theory that more is better and more than once was chastised for putting too much wood on and getting the fire too hot and thus not smoky enough. There was also a danger of actually cooking the meat but I had to learn the hard way.

Once that was behind you the results were well worth the work. There was nothing better than mother’s brown sugar cured and hickory smoked hams and bacon. Nothing at all like the water filled hams we get from the supermarket today or the extremely salty country hams marketed by the specialty brands.

As I write this, my mouth is watering and I’m reminded that I have a package of Morton’s Sugar Cure mix in the basement. I think I’ll talk to my local butcher about getting a small, fresh ham and see if I can come anywhere near the delicious product my mother produced. Probably not but hopefully it won’t be too bad.

Thanks Dub.

My folks differed on which way they liked their hams. My father preferred “sugar curing” described by Elmer above but my uncle kept a smoke house where he prepared his hams. The sugar cured meat had a stronger flavor it seemed to me and was a bit tougher to chew. But that is what my dad preferred. My mom always accompanied the ham with pan fried potatoes and biscuits for supper or ham and eggs with biscuits for breakfast.

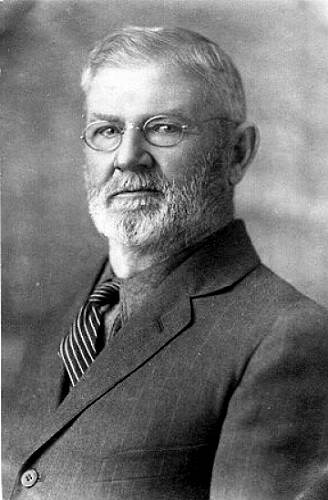

I am continuing again this week to feature the historical writings of Captain Henry Castrop (photo 07), an old time river boat captain who, in partnership with Captain Bob Marshall (photo 08), operated several steamboats up and down the Osage River (as well as the Missouri River) in the late 1800’s.

07 Captain Henry Castrop

08 Bob Marshall

I presented a biography of Captain Castrop in the Progress Notes for November 10, 2008. This week’s narrative by Captain Castrop is about the steamboats Frederick and the Hugo. Many people do not realize that the Tuscumbia steamboat entrepreneurs, especially Captains Castrop and Marshall, had an extremely successful business which included not just the Osage River but also the Missouri River. Captain Marshall was an astute businessman and was able to sell his shipping services to many types of customers for a wide variety of products. Some of the narrative below by Captain Castrop will give the reader an idea of the size, significance and importance of the steamboat shipping industry in the late 1800’s:

Steamers Frederick and Hugo on the Osage and Missouri Rivers

Captain Henry Castrop

Tuscumbia Autogram February 4, 1932

That the Hurlbut tried to satisfy her customers as best she could, could be proven by the shippers of those days, especially by those dealing in livestock, all of whom excepting Philip Balkenbusch, now residing near Linn, have for the last time wielded their whips to make the stubborn beast mind. These could tell how often the ice was broken during the winter to get their cattle and hogs to market. How at one time the channel at Rice’s shoals was deepened with scrapers may also be remembered by a few then working on the boat. John Wilde lived at St. Elizabeth, and if he were living he could yet recall memory some of the hardships and trials he went through while on this steamer.

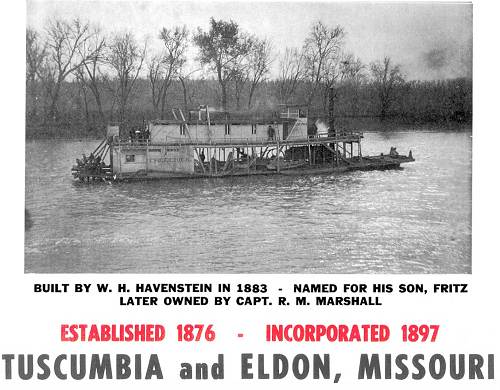

As it is the aim and zeal of all men in business to advance, so it was with us. Having run in the lower trade for several years, we concluded that the business should be expanded and take in the entire river, and this was effected when in 1888 our business was merged with that of the upper river then handled by the steamer “Frederick” and managed by Captain R. M. Marshall of Tuscumbia (photo 09).

09 Frederick

Prior to this period changes had also taken place in the Westphalia warehouses. My friend and first partner in business, Willie, was no longer here. He, too, had departed this life and gone to a better world beyond. The warehouse and thereto belonging farms were sold to the present owner, Stephen Mertensmeyer, who discontinued the warehouse leaving the entire business to the Westphalia (Brokers) landing, which, including the farm, in 1866 was bought and very successfully managed by my brother, Joe, until in the spring of 1918, when he sold out and moved to his present location in Saline county. The mail, after Willie’s death, was carried overland from Westphalia via Lisletown to Osage City; the first contract having been awarded to John G. Sonnen, at that time one of the most enterprising business men of Westphalia, who, in connection with the mail, also carried passengers and express between the two points. Sonnen’s career, after having served not only his interests but was also untiring in serving the welfare of his town. Westphalia owes much to him for its up building…ended when in the prime of his life, he died on his way home from the clinic at Latham, where he had sought relief when in the last stages of consumption. Being assisted from the train by his brother and the conductor, his last words were: “Good bye, boys, I am gone.” Seated in the waiting room he expired under the prayers for the dying said over him by the Reverend F. A. Diepenbrock who at the time happened to be at the station. Sonnen was taken home a corpse on the Hurlbut.

After the consolidation of the lower Osage River business with that of the upper, the new company incorporated under the name of Osage and Missouri River Packet Company with Captain “R. M. Marshall as manager and Captain F.G. Shoenen, agent.

The Frederick, to which steamer all the Hurlbut’s crew was transferred, with her barge, the Ida, then took care of all the business. The Hurlbut was sold to Captain C.S. Robey whose steamer, the Aggie, had sunk on a rock below the penitentiary at Jefferson City. The Hurlbut was no longer run in the trade but was dismantled by the new owner.

The Frederick was built in 1882 at Tuscumbia by Captain W.H. Hauenstein under supervision of Joseph Shepherd, an expert boat builder, who designed for her a hull not equaled by any. Her alignment was perfect throughout; her bow was of a model which would part the waters with ease. She was 100 feet in length, 14 foot beam, and 18 feet over all and built out of the best and most durable burr oak timber which insured her a life such as not many boats had (photo 10).

10 Steamer Frederick at Tuscumbia Landing

She plied on the Osage and Missouri rivers for more than a score of years with but little repairing done to her. She sank during 1903 or 1904. While lying at the wharf at Jefferson City, she one night sprang a leak and where now, after her boiler and engines were taken off, she lied buried in the river.

Captain Hauenstein (photo 11), after having operated the Frederick for a short time, sold one half interest in her to his brother in law, Captain Marshall, who a few years later became her sole owner.

11 William H. Hauenstein

The Frederick, a single deck boat, was, after the consolidation, fitted out with a cabin for the accommodation of passengers and crew. This improvement, however, was not to the steamer’s advantage. She being narrow, this made her top heavy and harder to handle in wind.

To make it possible to handle all the freight with one boat, the Frederick was run day and night. This required a double crew. Captain Marshall would be in the pilot house from noon until midnight after which he was relieved by me for the next twelve hours. Mr. Grant was chief engineer with Charles Jenkins as assistant. While Captain Marshall was master of the boat, I was assigned the office work. As a mate was dispensed with, the crew was handled by one of us then on duty as pilot when freight was loaded aboard or discharged at landings.

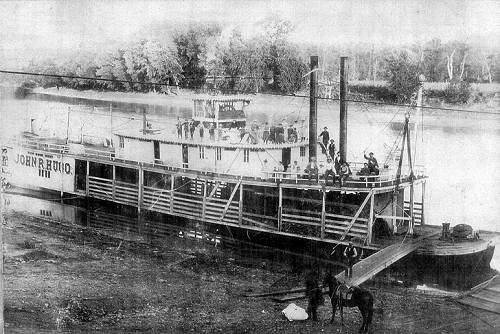

Scarcely a year after, our business, thanks to the exertion of Captain Marshall, had grown to such immensity that the Frederick was no longer able to carry all the freight offered on the Osage. Besides, there were offerings on the Missouri river which under prevailing conditions, could not be considered. And as prospects for a larger business became brighter, our company decided to buy another steamer. The John R. Hugo (photo 12) was bought and brought up from the Ohio River by Captain Alex Steward from Jefferson City.

12 John R. Hugo owned by Bob Marshall

The Hugo was remodeled from a 100 foot scow bow and lengthened out to a 141 foot model bow. The Jumbo, a barge 112 feet long and 5 feet deep, was purchased and brought up from St. Louis. The Hugo and this barge then were, in addition to the Frederick, put in the trade. All of the Frederick’s crew from the captain down to the fireman was transferred to the Hugo and the Frederick, though under the same management, was put in charge of another captain and crew.

By the efforts of Captain Marshall our company was granted exclusive of all other boats, a special low rate by the Missouri Pacific Railroad Company on up and down freight delivered to them at Osage. This low rate and possibly too, because Captain Marshall and myself were reared near the Osage River, and being citizens of their towns, gave us the patronage of the shipper. Very soon and we were without competition in the business which was in no way detrimental to the shipper but on the contrary, the inland towns were given much advantage. The granting of lower rates on freight to towns not on the railroad in those days was not in violation of the law.

In addition to wheat, livestock, country produce, merchandise, lumber, ties, lead and barites (tiff) were handled. Of this latter named product a mine was opened near Mary’s Home in Miller County and hauled to the river at the mouth of the Little Tavern. There was always tiff enough on the bank to load the boats and barges and when the sack piles were scarce the tiff pile was resorted to fill out the boat’s cargo on the down stream trip. As Captain Marshall had also contracted the delivery of cordwood to the State Penitentiary, many hundreds cords of wood were taken out of the Osage River as were also thousands of elm forks, and many boatloads of soft lumber from both the Osage and Missouri rivers, which forks and lumber were made up into saddle trees by the Sullivan Saddletree Company at the Missouri penitentiary. The cargoes delivered to this prison were unloaded by convicts under supervision of guards. One time after the boat was unloaded there was one prisoner found missing. He had hidden in the hull of the Hugo, but when discovered, jumped out from the hatch hole in the engine room and took for the river which he swam, but he had no more than reached the shore when he was hit in the leg by a bullet from the long range rifle of a guard and recaptured.

The Hugo was the largest steamboat owned by Captain Marshall. Unfortunately, it suffered a sudden fire and burned while on a trip to Nebraska. This story also is remembered by Captain Castrop:

Steamer Hugo Destroyed By Fire (photo 13)

13 Hugo Destroyed by Fire - Spring 1900

Tuscumbia Autogram (mid 1930’s)

Mr. Grant was only a short time in command of the Hugo. He died at his home in Carthage, Mo., in the fall of 1899. His interest in the company to which his two daughters fell heir was bought of them by Captain Frank G. Schoenen and myself. Captain W. L. Thompson was then placed in command of the Hugo, continuing work for the government until the spring of 1900, when this good steamer was destroyed by fire. While being tied up at the bank at Florence, Nebraska, the crew, with the exception of the watchman, being ashore attending a dance in the near by power house of the Omaha Waterworks. The fire, which apparently had started in the engine room, was discovered by the watchman, who at the time was on the upper deck. He at once blew the distress whistle and a few minutes later the water was turned on from the huge hose of the powerhouse and quickly extinguished the flames. But only her hull and boiler were saved. Her engines, by the heat and water, were cracked and ruined as was all of her machinery. After examining the wreck, I found it not advisable to rebuild the Hugo. Captain Thompson, assisted by two of his brothers, under took to float her down the Missouri river, and the 28th day after they started, the wreck was met above the mouth of the Osage by the Frederick and towed in and landed at the boatyards at Osage City. Her boiler and machinery were then removed from the hull which was converted into a barge. New engines, the same size and same model of the Hugo’s were cast, new machinery bought and the Hugo’s boiler, stacks, capstan and wheel shaft, which had not been hurt by the fire, were transferred onto a new model hull of 100 feet in length by 20 feet beam which had just been built by the company for a barge. This new boat, the Osage, fitted out with full cabin, after completion, ran for a little while on the Osage. But, alas, Captain F. G. Schoenen, who was proud of the stately new steamer, when he saw her depart for her initial trip upstream, saw her for the last time. When the Osage returned with a barge loaded to the guards with sacks, he lay a corpse in his home. A paralytic stroke had ended his life. His Life’s companion followed him in death one month later.

Frank G. Schoenen, Jr. then became my partner in the business. The Osage in the fall of 1900 took a fleet down for the government to Burlington Junction near St. Charles, where she remained towing for the government until winter. While I was engaged on the Missouri River with the Osage with first Captain Henry Keith and later Captain Grant Marsh as pilots, Frank G. Schoenen, Jr. ably managed the business on the Osage with the Frederick in charge of another captain. The Osage, in the spring of 1901, took a fleet up from the Ewing’s Boatyards to Atchison, Kansas, with Captain W. L. Thompson in the pilot house, Charles Jenkins, who had been Mr. grant’s assistant, in the engine room, and who after his death had advanced to chief engineer on that steamer, was in charge of the Osage’s engines from the time she was first launched until the time when she quit navigating the Osage and Missouri rivers. Mrs. Jenkins and my wife, she being my second, my first companion having departed this life in October, 1897, made their home on the Osage while she was employed on the Missouri River.

This last week our volunteers Nancy Thompson, Diane Berkbigler, Doris Wiggins, and Karen Smith (photo 14) were busy preparing for microfilming a large collection of record books from quite a few of the one room schools of the northern area of Miller County.

14 Nancy, Karen, Diane and Doris

This process involves wiping all the pages of these books to remove mold which is very contagious for old books for some reason. This mold can veritably destroy an entire library if it gets too far advanced. That is why the Missouri State Archives requires they thoroughly are cleaned before delivery for microfilming. We are very grateful to our volunteers for helping us with these types of activities which ultimately preserve for historians and genealogists records which otherwise would be lost or destroyed.

Notice:

The Miller County Historical Society board members recently approved some changes to our Constitution and Bylaws along with some Proposed Amendments. You can read the details by clicking the above links or by going to the "What's New" section (which can be found by clicking on the "About Us" drop down box on the left side of the home page) and then clicking on the announcement for November 5. The membership will have the opportunity to discuss and then vote on the changes at our December members' meeting.

That's all for this week.

|