|

Monday, July 14, 2008

Progress Notes

Miller County had one of its own farmers, Don Steen, selected by Governor Matt Blunt two weeks ago to become the new Director of Agriculture to replace the former Director, Katie Smith, who was stepping down for personal reasons. Refer to this newspaper link for the story:

http://www.newstribune.com/articles/2008/06/25/politics_and_elections/press_releases/189pr53.txt

Don, who has been a turkey farmer all his life, has also served the area in the past as state representative for two terms as well as up until now being the currently elected Miller County Assessor. Quite understandably my wife, who is Don’s sister, as well I and her family, were proud to have the governor select Don from among the many qualified candidates throughout the entire state of Missouri to be his choice for Director.

We and the rest of Don’s immediate family attended the swearing in ceremony last Monday, July, 7. I took a picture of him in his new office already decorated by him and his wife Alisa (photo 01).

01 New Director of Agriculture Don Steen

Alisa held the Bible for the swearing in ceremony officiated by Judge Mary Russell (photo 02).

02 Alisa and Don Steen - Judge Mary Russell

Don’s appointment suggested to me the idea to discuss the history of the poultry industry in Miller County which over the last seventy five years has been a very important economic resource for local farmers. Maybe it is news to some readers but the fact is, Miller County has long been one of the largest producers of poultry products of all the counties in Missouri and that Missouri itself is in the top five states of the nation in bringing poultry products to the market. Refer to this state government website survey done in 2002 to compare the various counties in regard to the number of turkey farms located within their boundaries:

http://www.nass.usda.gov/census/census02/volume1/mo/st29_2_013_013.pdf

According to this survey Miller County was second only to Morgan County in 2002 in regard to the number of turkey farms present. But according to an email sent me by Ted Fry, our local University Extension Agent, “… Miller Co. had over 2 million birds making it #1 in the state in turkeys.”

In fact, these days when you drive along about any rural road in Miller County you see on either side so many of the very long and low profile buildings used for raising turkeys that you hardly pay any attention to them anymore. That didn’t used to be the case when I was a young boy growing up sixty years ago.

The first person whom I consulted for some information about chicken raising was my mother, whose father, Madison Bear, ran a general store in Tuscumbia back in the 1920’s. Mom remembered that much of the trade then centered around bartering in which farmers traded produce for products they couldn’t make on the farm. The farmers brought in milk, eggs, butter and smoked pork for sale or trade. Mostly they wanted to buy or trade for sugar, flour, coffee and tobacco if they used it. Live chickens were traded or sold to the Farmer’s Exchange which had a store next to the Bears’ store. In those days, local town folk bought the live chickens and dressed them at home. But chicken raising mostly was for personal use, usually for obtaining the eggs as a food resource, with only the occasional chicken being sold or bartered. It was a special event if the farmer’s wife prepared a chicken for a meal because they were needed more for the food they produced from the eggs they laid.

Sometime later, to a certain extent before WW II, but much more afterward, the farmers saw that there was a market in selling live chickens in quantity to buyers who would take them to the city for processing for later sale to city residents. So in the 1940’s many farmers began raising chickens in much larger numbers than before, sometimes maybe a hundred or more, placing them in small sheds already on their property, or arranging space in an already existing barn. The demand for hatchlings created a need for hatcheries to supply the young poults, and the increased number of live grown chickens ready for the market created a need for processing plants to dress them before delivery to the retail outlets. Miller County was up to the task inspiring young entrepreneurs to start their own small businesses to handle most aspects of the poultry industry that was springing up rapidly in the post war period.

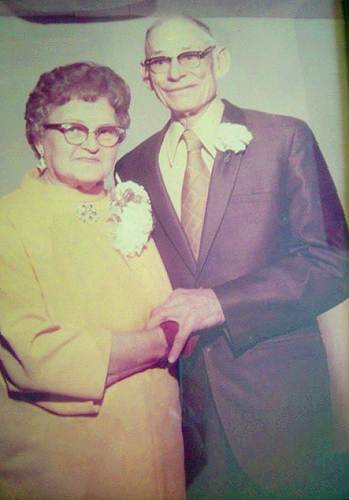

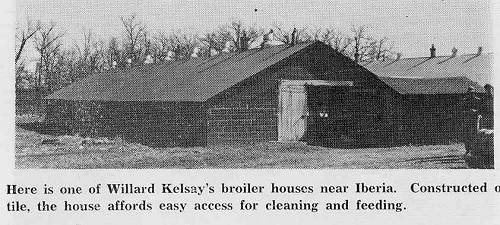

One of the families most involved early on in Miller County in raising poultry was that of Willard Kelsay (photo 03) whose farm was located north of Iberia near the Watkins/Hickory Point area.

03 Velma and Willard Kelsay

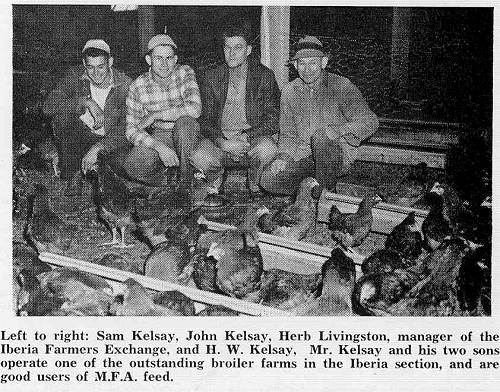

Willard started off small raising only a few broilers in the early 1940’s, but one day, Gene Waite of Eldon, who with his brother Norris owned the Central Missouri Turkey Hatchery, visited Willard and invited him to go see one of the first large poultry raising barns in the county at Mount Pleasant. Willard decided to accompany Gene to go over to Mount Pleasant to see the 120 by 30 foot building and was convinced to try his hand at large scale poultry raising. So in about 1945 he built not just one but two buildings for raising chickens with the help of his sons John and Sam (photo 04) and from then on the Kelsay family became known as running one of the largest poultry operations in the county. By 1953 they had five of the large buildings built for raising chickens.

04 Kelsay Family Broilers

Click image for larger view

The other day I went over to visit John and Carolyn Kelsay to find out more about the history of their poultry business (photo 05).

05 Carolyn and John Kelsay

John told me that as he became more involved with the business he not only raised chickens but also delivered feed to other area chicken raisers with one of his large trucks for the Gattemeir owned Olean Milling Company of Olean. In this way he met a lot of growers and established good relations such that often they would hire him to haul their chickens to processing plants where the chickens were prepared for sale to the retail market. Early on the only processing plants were in St. Louis, Kansas City or out of state even as far away as Nebraska. At one time John was delivering more than twenty thousand chickens weekly to various processing plants.

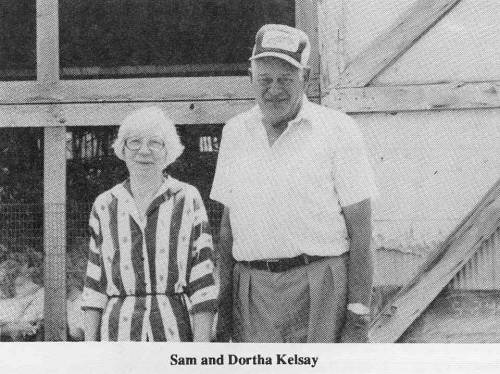

However, while local farmers such as John Kelsay and his brother, Sam (photo 06), were growing and producing chickens on their farms, others saw a niche for themselves by building processing plants and then delivering the dressed chickens to the grocery stores in their own trucks.

06 Sam and Dortha Kelsay

So instead of the local farmer having to pay for delivery of his chickens to far away processing plants, local people in the area began buying and processing chickens here.

I went over to LaRue and Rosette Rush’s home near Tuscumbia (photo 06a) last week to learn more about the processing plant history locally.

06a LaRue and Rosette Rush

The following is a summary of what he told me and includes photos he has saved from newspaper articles from the past:

The processing industry of Miller County began in Tuscumbia in 1954 when Denzel Slone and Kern Newton started the “Ozark Poultry Company” in a building Denzel owned which he had formerly used as a locker plant storage business. Sometime after that, perhaps within a year, Denzel sold the business to Hig Atkison. Later Hig moved the operation to his farm and Denzel reopened his business once again keeping the name Ozark Poultry.

In 1957 Hig was joined by Clyde and Carl Hawken and the business was moved to a location just south of the Osage River bridge on the west side of highway 52. The name given to their company was Riverview Poultry. In 1958 LaRue Rush purchased Carl Hawken’s interest. The next ten years were hugely successful for Riverview Poultry as will be described below in an article from the Autogram from that time period.

In 1967 the Atwill brothers purchased Ozark Poultry from Denzel Slone. Soon afterward this company merged with Riverview Poultry and the owners chose the name O & R as the name of the new larger company, keeping all operations at the location south of the river.

By this time, especially with the merger of the two companies, O & R was one of the largest poultry processing plants in the state. Fifty thousand chickens were processed weekly and sold throughout mid Missouri to local groceries. Gerbe’s Supermarket chain was one of its early customers and as Gerbe’s began to grow, placing multiple stores throughout mid Missouri, so did O & R Poultry.

Some of the names of employees at O & R will be familiar to Tuscumbia residents. In beginning, Melvin Thomas and Jim Matthews were on the road constantly driving large trucks to local farms to load the chickens. Later LaRue Rush’s brothers Bob and Gerald as well as his father Roy were involved with the loading and delivering of live chickens to the plant. Young men and boys of the community earned extra money catching the chickens eight at a time and loading them in the cages on the trucks. The farmers were paid at “one cent over Arkansas” meaning the current market price paid per pound in that state.

Twelve delivery trucks were on the road everyday delivering dressed chickens to grocery stores and supermarkets. The drivers were given bonuses for the sales they made. Some of the drivers included Lonnie Ahart, Frank Martin, LaRue Rush, Harley Humphrey, Raymond Beard, Glen Smith, and Ervin Siegel.

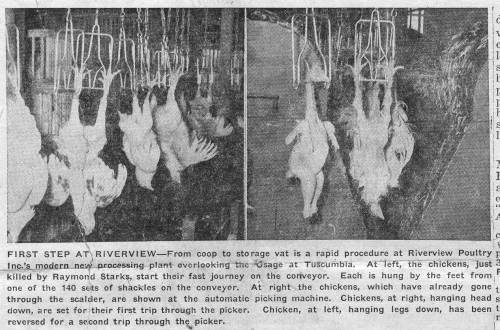

In 1957 when the Riverview Poultry Company to which I referred above was very active but before it merged with Ozark Poultry Company, the Autogram published an article which gave the details of how the chickens were processed.

Note: The following information possibly could be more than you want to know about this aspect of the poultry industry so scroll or skip past it if you find it too graphic:

Miller County Autogram

Thursday, May 2, 1957

“Assembly Line Production At Riverview Plant”

Assembly line production is down to a fine point at Riverview Poultry, Inc.’s new processing plant on a bluff overlooking the Osage River south across the Highway 17 bridge from Tuscumbia. At peak operations the plant can process 1600 chickens an hour-from coops to iced storage vats, all ready for delivery. Owners of this growing Miller County enterprise are H.C. Atkison, Cyde Hawken and Carl Hawken. The modern plant represents an investment “in the neighborhood of $20,000,” Atkison said.

“It’s as near fireproof as we could make it,” he said, as he showed an Autogram reporter and photographer the company’s new 35x50 foot cinder block building.

Future Additions Planned

The company, in its new location little more than a month, still has some additional installations and finishing touches to make.

Plans call for the future installation of a second picking machine, and the partitioning off of another small room in one plant where chickens will be cut up and tray packed. The office, at the front, is still unfurnished, too.

“Riverview” is an appropriate name for the company. From the double doors at the rear of the building, one can look out across the attractive Osage valley to the community of Tuscumbia across the river.

Automatic operations

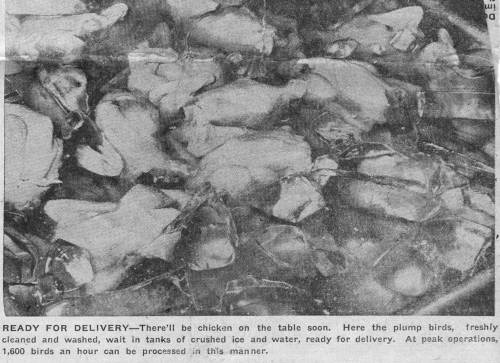

Operations in the processing procedure begin in a room at the rear where the chickens are killed and hung on individual shackles which swing from the continuously moving conveyor. From there the chickens automatically move through the scalder, then through the picker, and come around to the evisceration trough, then are drawn, washed and put it tanks of crushed ice and water, ready for delivery.

“It’s running about as slow as it will go right now,” Atkison said Friday morning, “and we’re turning out 420 birds an hour.”

At 9:45, when the reporters left, the staff had already processed right at 600 birds since 8 o’clock. At present the birds are reversed so they will go through the picker a second time.

“Later we plan to install a second picker, so it won’t be necessary to reverse them,” Atkison said. “Right now, you’ll notice we’re putting a bird only on every other hook, so we can reverse them. Later, with the added machine, we can put a bird on every hook. This second picker will about double production.”

Four on road

In addition to the 11 plant employees, the company has four men on the road almost daily, making deliveries with the company’s fleet of five trucks. These are LaRue Rush, Carl Hawken, Lonnie Ahart and Glen Smith.

Lots of water is required in the plant operation, so Riverview has its own 300 foot well. The conveyor is electrically operated, and a gas fired furnace heats the scalder.

Riverview Poultry, Inc. is a local enterprise from all angles. Most all the poultry processed there is purchased within 15 miles of Tuscumbia. Those being processed Friday were from Jim Robinett’s farm just three miles from the plant.

Most of the birds, Atkison said, are specially raised to meet requirements. The company has no contracts with producers, but keeps in touch with them to know when their flocks will be ready then goes out and buys and dresses the birds as needed to supply the demand.

Marketing outlets for the dressed birds are supermarkets, cafes, and groceries in the area.

The Atkisons were in the processing business almost six years at their farm on Highway 17 north of Tuscumbia until the move to the new plant. The Kern Newtons were in partnership with them until July 1955, when the Atkisons acquired full ownership.

Last fall, the Hawkens’ recently returned from Alaska, bought interests in the business, and the name was changed from Atkison Poultry Company to the new corporation name carrying out the river theme. At that time the new corporation announced plans for it expansion program.

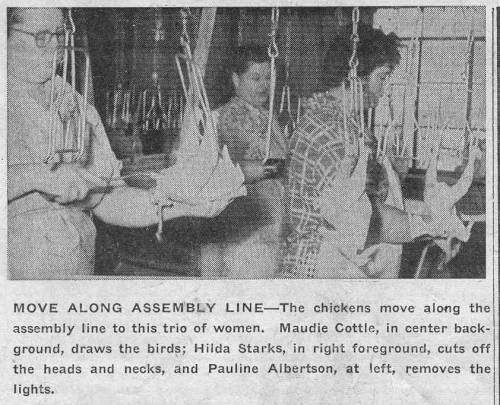

The following series of photos feature some of the employees and their names who worked in the processing plant and depicts the various tasks they were performing (photo 06b, 06c, 06d, 06e, 06f and 06g).

06b Processing 1

Click image for larger view

06c Processing 2

Click image for larger view

06d Processing 3

Click image for larger view

06e Processing 4

Click image for larger view

06f Processing 5

Click image for larger view

06g Processing 6

Click image for larger view

In the late 1960’s federal inspection requirements began to be imposed at the processing plants which when combined with the supply/demand curve lowering the price per pound paid to growers created a situation which was not as profitable as before. This caused a significant change in the Miller County poultry industry so that by the early 1970’s no chicken processing was done locally.

At that time John Kelsay began delivering his and other growers’ chickens to a plant in Jackson, Mo. But by 1975 the price per pound being paid for poultry had dropped to less than 18 cents which was a break even point for most growers. So in 1975 John decided to concentrate on raising turkeys. Most other chicken farmers also either quit the poultry raising altogether or else changed over to turkeys.

Soon John was raising up to sixty thousand turkeys yearly under contract, first to Ralston then later to Cargill. His sons Bill and Ricky (photo 07) joined him in the turkey operation building structures on their own farms to raise them. John retired in 2000 and now his sons together are producing for the market between 150,000 to 200,000 turkeys yearly.

07 Belinda. Carolyn, Ricky, John and Billy Kelsey

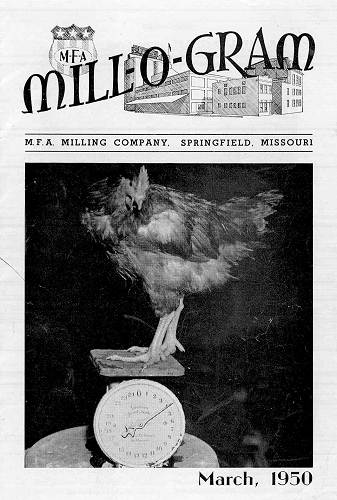

Some years ago, when Willard, John’s father, was actively involved in chicken raising, MFA was so impressed with his operation that it was highlighted in one of MFA’s publications. I have copied it below:

Mill-O-Gram

March, 1950

Miller Countian Profits From M.F.A. Fed Broilers

Good chicks, good management and the M.F.A. feeding program are the “big three” that has enabled H. W. Kelsay, of near Iberia, to set an example in that region as an outstanding broiler producer.

Kelsay has a 294 acre farm in Miller County, Missouri, northwest of Iberia, but he devotes all of his time to the broiler production business, leaving his two sons, John and Sam, to operate the remainder of the farm and to assist in the broiler business On February 28th, Kelsay had 5300 New Hampshire broilers, 12 weeks old, that were to be trucked to the market the following day. These birds averaged from 3.6 to 4 pounds each, and Kelsay had them already sold at a price of 29 cents per pound. Figuring on the basis of what his earlier batches had brought, Kelsay believed he would clear, above feed and other costs, somewhere between $1800 and $2000 on this one operation. An interesting sidelight on this flock was revealed by Herb Livingston, manager of the Farmers Exchange at Iberia, who explained that Kelsay was selling more chickens than he actually purchased, since he had only lost a few of the extras.

In addition to the 5300 broilers sold March 1st Kelsay also had 5300 birds in a second broiler house that were 7 weeks and 3 days old on February 28th. They would be ready for the market by the latter part of March, if not sooner.

Kelsay, in describing his operations, explained that he used the complete M.F.A. feeding program, purchasing all of his feed from the Ibera Farmers Exchange. He said his chicks get their start on M.F.A. Chick Starter, which is fed them for about 5 weeks. They are then switched to M.F.A. Broiler Feed for three weeks, and for the remainder of the time before they are sold they get M.F.A. Broiler Finisher.

In talking with Manager Livingston of the Iberia Exchange, Kelsay said he likes M.F.A. feeds better than anything he has ever used.

“This M.F.A poultry feed makes me more money, and does a far better job. I’ve tried several different kinds of feed down through the years, but M.F.A. feed certainly does the best.” Continuing, Kelsay pointed out, “Why, I would be foolish to pay a high price for feed when I can get M.F.A. feeds so much cheaper and have them do such a better production job.”

Kelsay, a long time broiler production man, has two broiler houses, 30 x 120, constructed of tile with aluminum roofing. He uses gas, fuel oil and wood to heat, depending on the wood to keep the houses a little drier in the winter months (photo 08).

08 Early Broiler House

In checking over his records Kelsay pointed out that in November he sold a batch of 5200 broilers that were 12 weeks old, which netted clear exactly $2003. “I’m certainly a believer in the broiler business for the Ozarks region,” he emphasized.

Mr. and Mrs. Kelsay, besides their two sons, also have two daughters, Joyce, of the home, and Wanda Lee, who is a student at Southwest State College in Springfield.

Other operations on the Kelsay farm, and to which John and Sam devote their spare time, includes the raising of registered Hereford cattle. They also have 9 sheep and 15 hogs.

Last spring, Kelsay explained, he raised 3000 turkeys in one of the broiler houses, but since then is devoting all of his facilities to broiler production.

“Broiler raising is much easier work,” he explained. “Besides, the broiler raisers here in the area served by the M.F.A. Milling Company have a lot of advantages that persons in other sections of the country don’t have.”

Manager Livingston, on the way back to Iberia after the visit to the Kelsay farm, explained, “This fellow Kelsay is certainly a fine farmer, and he sure knows his business when it comes to raising broilers. His operation speaks highly for both his ability and his management practices.”

The cover of the magazine, Mill O Gram, from which the above article was copied, featured one of Sam’s chickens which reached four pounds in only eight weeks (photo 09).

09 Willard Kelsay's Champion Weight Chicken

As I was talking to John about his and his father’s poultry business, he mentioned that one of his mother’s uncles, George Forester, helped out on their farm once in a while. George never married but traveled around quite a bit going to Kansas to work on farms quite often if work was scarce here. I happened to remember that my great grandmother, Susanna (Susie) Abbett’s maiden name was Forester and I had heard not infrequently in the past of George Forester. George and my great grandmother were brother and sister. In fact, George toward the end of his life, lived in a room in my grandmother’s basement in her home in Tuscumbia. My grandmother, Sadie (Abbett) Bear was Susie (Forester) Abbett’s daughter. George died there quietly in his sleep one night. I don’t think he had any immediate family then and had no other place to go. Here is a photo of Jim Bob Forester, brother to George; my great grandmother, Susie Forester Abbett; and George Forester (photo 10).

Abbett-GeorgeForester.jpg)

10 Jim Bob Forester, Susie (Forester) Abbett and George Forester

Willard Kelsay mainly raised chickens and never got into turkey production although his son, John, as noted above, changed from chickens to turkeys in 1975. Another Miller County farmer, Holmes Steen, began raising turkeys from the beginning. His operation, which was one of the first large turkey farms in the county, was one which I, naturally, knew quite a bit about since he was my father in law. In 1943 after returning from working in Colorado for the U.S. Government during WW II Holmes began to raise turkeys on a small farm on the banks of the Osage River near Bagnell, Missouri (photo 11).

11 Holmes and daughter Sharon - 1943

In those days the young turkeys were kept in a brooder house until they were about six to eight weeks old, then they were released to open areas in fields and woods until they were ready for the market. It wasn’t until much later in the early 1970’s that turkeys were raised confined to large specialized buildings until ready for transfer to a processing plant without ever being turned outdoors into a field.

After several floods Holmes decided to move to a ridge farm about three miles down the river where he could be far enough up the hill to not be flooded. This farm, by the way, had been owned in the past by the famous river boat captain, John Adcock, who was in charge of the J.R. Wells during the late 1800’s, one of the largest steamboats to navigate the Osage River. Elva, Holmes’ widow, still lives in the original Adcock built house.

Holmes, for a short time, had the distinction of having built the largest brooder house in Miller County (photo 12).

12 Large Brooder House

However, turkey raising was becoming so popular around the county that brooder houses of ever increasing size were being built and I don’t know who ended up ultimately with the biggest one. It became a moot point anyway when the farmers began using the large confinement buildings where the turkeys remained until ready for shipment to the processing plants.

Holmes’ building still exists but no longer is utilized for turkey raising; in fact, Mrs. Steen, who has been a widow for twenty five years, uses it as a store house for her semi annual “brooder house” sale of house hold items she has collected for resale from various sources. This is a kind of hobby for her. By the way, when you see her announcement in the paper about the next sale, you might want to stop by. One day I found a genuine Civil War buckle identified as belonging to a soldier for the North in one of her unopened boxes she had gotten at an estate sale somewhere. We identified it as genuine and it now is on display at the Miller County Museum in Tuscumbia (photo 12a).

12a Civil War Buckle

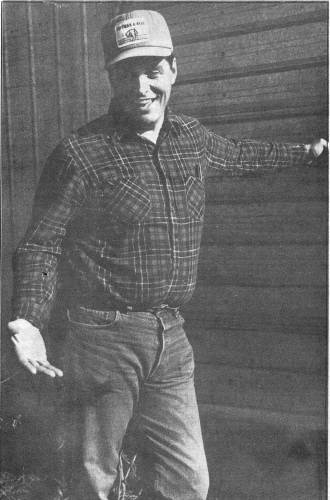

The modern method of raising turkeys in large confinement buildings became popular in the early 1970’s. When Don Steen, Holmes’ son, began raising turkeys in 1973 he started right away using the large confinement building method for raising the turkeys. A couple of articles written by local newspapers about Don’s operation are interesting to read and I have copied them here. Although the articles were published quite a few years ago, they still are relevant to today’s method of raising turkeys:

News Tribune

Jefferson City, Mo.

November 24, 1991

Don Steen (photo 13) frets like a mother hen over his flock of 6600 turkeys. From the time they arrive on his Miller County farm one day old until he sends them to market at 18 weeks, a lot of things can go wrong.

13 Don Steen

A low flying jet could strike terror among them, eliciting a natural tendency to pile up and suffocate. He once lost 1500 turkeys that way.

Little ones could lose their way to the feed, starving to death. A small percentage of his flock dies of starvation.

Or they could get too fat too soon for their organs to handle it and die of hear attacks. He loses three to five turkeys a day that way.

“See that sick one over there,” Steen says, pointing to one turkey noticeably smaller and weaker than the others. “He has to fight for his life every day. In two to three days he’ll be dead….the other turkeys will kill it. It’s kind of a pecking order thing.”

But the other turkeys filling the barn the length of two football fields were fat and healthy with three weeks remaining in their lives.

These will be cold cuts and pot pies after the first of the year,” he said.

Checking on his turkeys several times a day is a big time commitment that Steen juggles around his schedule as a state representative. The Republican was elected last year to the House seat that covers Miller County and parts of Cole and Camden counties.

Sometimes the jobs rub off on each other.

“I go to work at the Capitol with manure on my shoes a lot of times,” he said. “No one sees it until I cross my legs!”

One day, House debate turned to the identity of “the other white meat”…between Steen and Republican Rep. Dale Whiteside, a Chillicothe hog farmer.

Steen says he’s learned a lot during his first year as an elected state official, but his life is still turkeys.

“I know more about turkeys than anything else in the world,” he says. The day Steen was born 42 years ago his father was roofing a new turkey barn on the family farm. At that time it was the biggest turkey house in Miller County.

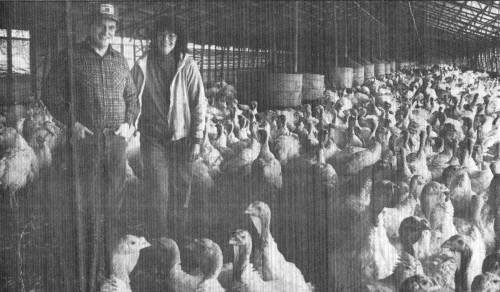

When Steen married his wife Alisa in 1973, they bought the neighboring farm and went into the turkey business on their own (photo 14).

14 Don and Alisa Steen in their large Confinement Building

Steens’ have been raising turkeys for 48 straight years in Miller County, the top turkey producing county in Missouri, which ranks among the top five states in gobblers.

In that time, a lot of changes have occurred in turkey production; most of them spurred by dramatic increases in turkey consumption…a 60 percent increase in the past five years.

Turkeys used to be “ranged” outside, so they could only be raised in warm weather. In the past 15 years, Steen said, increased demand for turkey has led to year round production, so turkeys are now raised most of their lives in barns.

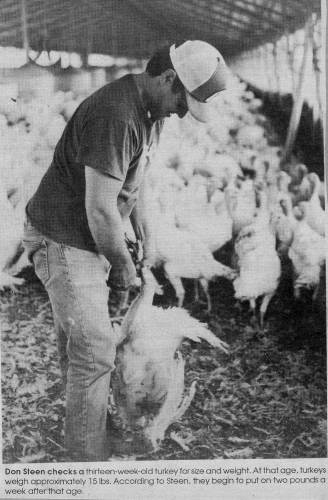

They’ve also been genetically altered. Steen’s father, Holmes, raised black turkeys that grew to no more than 25 pounds in 25 weeks. Today, turkeys are white, which is easier for processors to clean, and the birds grow to 30 pounds in just 18 weeks (photo 15).

15 Don Steen Checking Weight

Click image for larger view

More fat is now incorporated in turkeys to make them more tender and tasty so they can be cooked a variety of ways, he said.

Despite the increase in consumption, Steen said the turkey market is now unfavorable for producers. Production not only caught up with demand, it surpassed it and now there is a glut of turkeys, driving the price down.

About 21 million turkeys were raised in Missouri during the year ending August 31, according to a report from the Department of Agriculture. That was up 17 percent from the year before.

“We’ve got to move more turkeys this holiday season or we’re sunk,” Steen said.

It costs Steen about $10 to raise a turkey. He figures it has to sell to the consumer for at least 50 cents a pound for producers and processors to break even. But turkeys are selling in Jefferson City grocer stores this week for around 45 cents a pound.

Because Steen raises a larger type of turkey, his are sold as processed meat, such as turkey hot dogs, bologna, pot pies and turkey parts.

They begin at his farm one day old. The temperature in the barn has to be 95 degrees to keep them warm enough that they don’t pile up and suffocate. Feed and water must be nearby so they can find it.

“I almost live with them the first few days,” Steen said. “If a stove goes out they could die in 10 minutes.”

Then each week the temperature is dropped 5 degrees until they’re big enough to live comfortably at 70 degrees.

Steen insists it’s a myth that turkeys are dumb. “A lot of times I think they’re much smarter than people give them credit for.”

He said it’s not true that they’ll hold up their heads in the rain and drown. They’re inquisitive birds and prefer a routine, he said.

If Steen wears something other than his usual hooded blue sweatshirt into the turkey barn, they throw a fit. Even a discarded candy wrapper on the ground will make them stop short because they’ve never seen it.

Knowing these traits makes them easy to drive and work with, he said.

“You’ve got to understand the mentality of a turkey so you know what it’s going to do,” Steen said.

He’s sensitive to complaints from animal rights activists that turkeys are mistreated.

“These turkeys are happy,” he argued. “They don’t get too cold or too hot. They don’t get rained on. They don’t have to worry about a fox.”

Furthermore, their beaks are clipped so they don’t peck each other to death, he said.

He added that the controversy is “going to have to be addressed in the next several years.”

When Steen was elected to the Legislature he reduced the number of turkeys produced and Mrs. Steen assumed more of the responsibility for the farm. Their two sons also work with the turkeys and a herd of Simmentals.

But Steen said he plans to remain predominantly a farmer. He loathes the trend by legislators to make that their only job. He believes that leads them to making decisions for the wrong reason…to get reelected.

Although he believes his five generations of roots in Miller County help him to reflect the views of his constituents, he says he still will always vote his conscience.

“If they don’t like it, I’ll go back to raising turkeys full time.”

Another article by the Eldon Advertiser adds some more information about turkey farming as told by Don:

Eldon Advertiser Special Edition:

1988 Turkey Festival

Lorie Kiso

Don says he has been involved with the longest running turkey operation in Miller County. His father, Holmes, began raising turkeys in 1943 after returning from a war related work camp in Colorado. Although having been raised south of Iberia, where his brother, Waldo Steen also soon began raising turkeys, Holmes decided to move to a river farm just north of the town of Bagnell close to where the Osage National Golf Course now is located. In 1949, the family bought another farm located on down the river closer to Tuscumbia onto the old Adcock farm, once owned by famous steamboat captain, John Adcock.

Don began raising turkeys himself in 1973. One of his major concerns raising turkeys is to make sure the floor is kept in good condition. “If the floor is too wet, the turkeys burn the pads of their feet,” he says.

More than 40,000 turkeys grow up at the Steen farm each year. Once every 13 weeks, about 11000 day old poults are brought to the farm. Steen raises four flocks of turkeys each year.

The poults stay in the brooder house for about six weeks and then they are herded into the growout house that sits not too far away.

When the turkeys reach 13 weeks old, Steen receives another shipment of the day old poults. The young turkeys stay in the brooder house until they are 18 to 20 weeks old when they are taken to market.

The “big house” or grow out house is only empty one week at a time for four weeks out of the year, Steen said.

In the 270 x 40 foot brooder house, one square foot is required for each turkey. In the 650 x 40 foot grow out house, approximately three and one quarter square feet is required to raise each bird.

Steen’s father, Holmes, was the first one in the county to build a 165 foot long grow out house for the birds. “At that time (in 1949) that was the longest turkey house in Miller County.” It soon became obsolete, though. “Everybody built bigger buildings after that,” he said.

There are many different systems used in raising turkeys, Steen said. Steen contracts with Swift of Huntsville, Arkansas, on a floor or independent contract. “On a floor contract, the turkeys belong to me. I buy the turkeys and the feed and then Swift dresses them and reimburses me for the feed costs and the poult costs in addition to giving me an additional amount for my labor,” he said.

With the independent contract, Steen foots a “lot of risk.” If by chance, the turkeys die, he is left to absorb the cost of the feed and the cost of the bird. But, if everything goes as planned, he ends up making more money on the contract.

All of the turkeys raised on the Steen farm finish at a weight of 25 to 30 pounds, and are used for further processing including turkey rolls, turkey wieners, and turkey cold cuts.

The most popular sized whole bird weighs 15 to 16 pounds. These birds are most often hens, Steen said.

Steen has seen many changes in the turkey growing industry since he started raising the birds. At one time, turkeys were raised outside. That is now a thing of the past, since turkeys can be raised year round instead of just May through November. “Inside there is a more controlled environment and the turkeys aren’t as susceptible to disease and being killed by varmints,” he said.

As for the future of turkey farming, Steen says he sees a healthy market. “There continues to be a need for more turkeys to be raised since it is a good food for health conscious individuals,” he said.

Another part of the poultry industry in Miller County associated with the raising of turkeys was the hatchery from where the young turkey poults originated. The largest hatchery in this area was that started by Norris and Gene Waite in Eldon. Norris and Gene were raised south of the river in the old town of Watkins, located a few miles down KK off highway 17 south of the Osage River. Both of them went to Tuscumbia High School. But they saw a need to supply the turkey farmers with young poults from a local hatchery which they established in Eldon. Also a feed business was associated with the operation too. After several years Norris took over the feed operation and Gene continued with the hatchery. The hatchery building is still standing at Fifth and Mill Street (photo 16) although it is now being used for furniture storage.

16 Central Missouri Turkey Hatchery

I have been told that not only did the brothers supply the young hatchlings and feed but they also helped the local turkey farmers get the best buyer’s price when the turkeys were ready for delivery to the market. This was before the farmers had the opportunity to contract their turkeys out to one of the large corporations.

As time went by the big corporate interests in the poultry business began competing with the local small raisers not only here but across the nation. As the business became more competitive farmers found it easier to contract with the large corporations with a set guarantee rather than continue as independent contractors. Early on Swift and Ralston Purina were active in Miller County but now Cargill has many of the turkey contracts in the area. The Rush family mentioned above contracts with Con-Agra.

Another part of the poultry industry years ago in Miller County (1950’s and 60’s) was the production of eggs by caged laying hens confined to buildings with special ventilation and drainage. The cages were designed so that the eggs would slide down a trough as soon as they were expelled by the hen such that no contamination reached the shell. The ventilation and emphasis on cleanliness was intended to produce eggs which were healthier for human consumption as well as creating a healthier environment for the laying hens. However, this aspect of poultry farming didn’t last long here because of our high humidity in the hot summers which created many unexpected problems. The litter that accumulated on the floor became wet due to the humidity which was more intense than what the ventilation systems could handle and was a perfect media for contamination due to the growth of harmful bacteria. Mold grew on the walls and doors and the chickens instead of being healthier were actually worse off than being outside. Apparently, this system worked well in other areas of the country but not here. Egg production by caged laying hens did not last for more than ten years around here to any great extent. I remember my father in law, Holmes Steen, had one of these caged hen egg production systems and it seemed he spent more time trying to keep the building clean and his egg laying hens healthy than time spent in any other area of his farming operation. Soon after he ceased running his egg production facility the building burned down. I guess it just wasn’t meant to be.

Recently, during the writing of this narrative I got a note from Sherril Steen, originally from Iberia and son of Waldo Steen. Waldo, who was a brother to Holmes Steen, also was one of the early Miller County farmers to enter the area of poultry raising as a major business endeavor for his farm. What makes Waldo’s story interesting is that he was one of the first to enter into the poultry business in a significant manner and his story of beginning small but eventually expanding into other areas of earning income from the poultry industry is somewhat typical of those early days of the poultry farmer. The following are the memories of Sherril about his father’s poultry business when he was a young boy:

Memories of Waldo Steen’s poultry farm

Sherril Steen

I was born in 1936 and Dad was in the egg business before the war started in Dec of 41. My early recollection was of Dad candling eggs in the basement of what we called the 30 X 30. He also had laying hens in the 20 X 20. The hens ran free inside the houses--never outside. Dad built "roosts" for the hens to sleep on in both houses. He ground and mixed his own feed and hatched his own chickens. The incubators were in the basement of the "well house." The Bank of Brumley financed Dad's operation from about 1932 to 1949.

Dad and Uncle Holmes (Steen) worked as carpenters during the early war years. Aunt Elva (wife of Holmes) thinks until late '43 or early '44. In this family photo Waldo is on the exteme left and Holmes on the extreme right of the back row (photo 16a).

16a Waldo, John, Paul, Kermit, Holmes, Vergie, Frank, Ellie and Icie

After the camps (Ft. Wood, MO; Neosho, MO & Pando, CO) were finished, Dad and Uncle Homes started raising turkeys. The feed all came from Anchor Milling Co., down by the river. Norris Waite provided the baby turkeys. Dad raised 2000 per year, 4000 in two flocks in 1947. The birds were kept in the houses for about 3 months, and then put on range until they weighed about 20 pounds. Dad also built roosts for the turkeys to sleep on. The roosts were about 4 feet above the ground. He simply put several rows of posts in the ground and put small poles across each row of posts. Each row was about 2 feet apart. Clyde Head from Crocker, MO was usually the broker that found a buyer for the turkeys.

Dad and the Bank of Brumley were always at risk on the turkeys until the late 40's and early 50's, when the financing was taken over by General Mills. By that time, the risks were unbearable for a small bank like the Bank of Brumley. Dad always owned the turkeys, that is, he was an independent grower.

We always had a few cows to provide milk for the family of 11 and a little cash from selling cream each week. The red silo by the barn was used for silage to feed the cows and calves.

The elevator south of the house was built in 1948 and '49 to store grain for the turkeys and later hogs (photo 16b). His dream was to mix his own feed, but he never accomplished that.

16b Waldo's Grain Barn

Thanks Sherril.

For more detailed information about broiler farms this website at Wikipedia is interesting:

http://en.wikipedia.org/wiki/Broiler

For more information about turkeys go to Wikipedia again here:

http://en.wikipedia.org/wiki/Turkey_%28domesticated%29

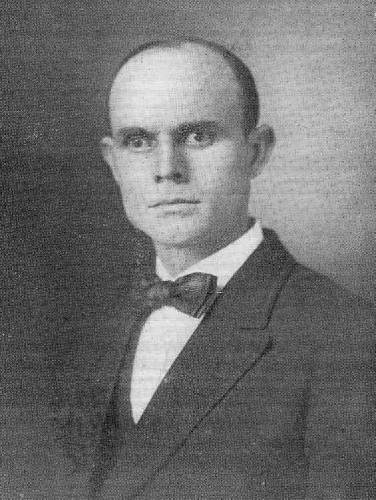

A couple of weeks ago I wrote about the early educators of Miller County one of them being T.E. Vaughan, who was one of the first superintendents of the Eldon school system. I mentioned that I couldn’t find out much about his family history or even what names the initials T.E. represented. I think I may have solved this mystery. My uncle David Bear, who is going on 91 years of age, remembers T.E. Vaughan, saying that he was the son of Wilson Vaughan of Tuscumbia. I looked up an old family photo I had of the Wilson Vaughan family (thanks to Mike Wieneman) and found a young boy pictured whose name was Thomas Everett Vaughan (photo 17).

17 Tressa, Theron, Jacob, Ethel Zene, Eric Lyman, Wilson Milton,

Thomas Everett, Lafayette Cordell and Floyd Estel Vaughan

When one compares this picture to one of T.E. Vaughan as an adult, I think striking similarities are demonstrated, especially in the eyes (photo 18). So all things considered I believe that T.E. Vaughan originally was from Tuscumbia.

18 T. E. Vaughan

I called LeRoy Vaughan of Tuscumbia for some more information about Wilson. LeRoy told me that Wilson Vaughan was his grandfather. Wilson Vaughan’s first wife was Rachel Scott and they had eight children. After she died he lived for less than a year with a Martin woman but LeRoy doesn’t remember her first name. Wilson’s second wife was Destia with whom he had eleven children. Wilson was living then near the Osage River on the Tuscumbia Bagnell road about six miles from Tuscumbia. First he had a farm on west of Gum Creek (later owned by Glen Warren) and then a farm on Gum Creek closer to Tuscumbia. Here is a photo of Wilson when he was very old (photo 19).

19 Wilson Milton Vaughan

I also received a message from Mike Wienemann who confirmed that T.E. Vaughan, indeed was the son of Wilson Vaughan of Tuscumbia. Here is what Mike wrote:

Joe,

Thomas Everett Vaughan, T.E. Vaughan, and Professor Vaughan are all the same person. You are right about that. He was a son of Wilson and Jane (Scott) Vaughan. He was my mother’s cousin. He wore a patch over one eye years later. I have quite a bit of information about him.

Mike

I also found two obituaries about Wilson Vaughan, T.E.’s father:

News Item and Obituary: Unknown Publication, October 1950:

One of Miller County’s oldest citizens, if not the oldest, passed away last Sunday at the age of 99 years and 10 months. He was Mr. Wilson M. Vaughan who had been making his home with the John Moneymakers of RFD 2, Brumley. Funeral services were held last Tuesday at the Tuscumbia Baptist Church at 2 p.m., the Rev. Frank Chase officiating. Interment was made in the Scott Cemetery near Tuscumbia. Arrangements were under direction of Hedges Funeral Home of Iberia, Mo.

Obituary: Unknown Publication

Wilson M. Vaughan, son of Joshaua and Elizabeth Vaughan, was born Dec. 5, 1850 in Moniteau County, Mo., and passed away Sunday, Oct. 15, 1950, at the John Moneymaker home, Rt. 2, Brumley, Mo., at the age of 99 years, 10 months and 10 days.

In 1874 he was united in marriage to Rachel Jane Scott, and to this union 8 children were born. In 1896, he was united in marriage to Destia (Dusty) Lee Dobson with whom he had eleven children. Preceding him in death were 3 sisters and 7 brothers. He is survived by 14 children. Five preceded him in death. Also surviving are 67 grandchildren, 42 great-grandchildren and 3 great-great-grandchildren and many other relatives and friends.

My mother tells me she remembers Wilson Vaughan since he would walk to town pretty regularly when she was a young girl. At that time he was already very old and the children had grown up and left home.

In summary, I am really impressed that Professor T.E. Vaughan, as he was called in his later years, overcame the deprived circumstances that such a large family would present to become a learned educator and successful leader. As I noted in my essay about him two weeks ago, he was a much respected individual who helped the Eldon school system organize and grow during its very early years of existence.

That's all for this week.

|