|

Sunday, August 12, 2007

Progress Notes

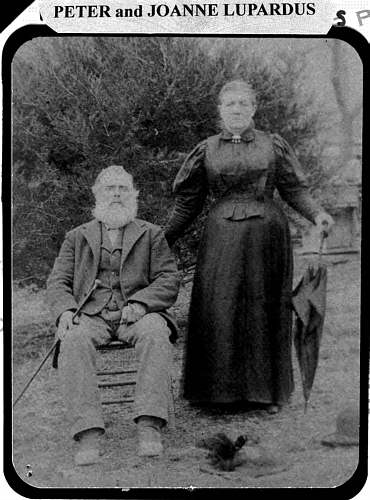

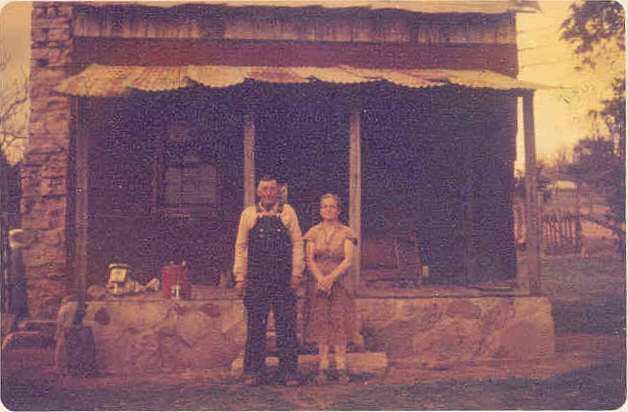

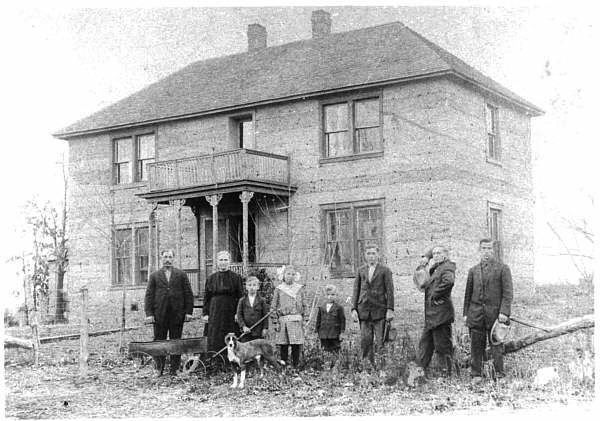

Last week the museum had the pleasure of the visit of Lena Bear, Lucille Brightwell and Doris Porter (photo 1). The three women are sisters, the daughters of Will Brown, and whose mother, Bessie, was a daughter of Peter and Joanne Lupardus (photo 2). Peter was the one who built the old cabin which a few years ago was transferred to the museum site (photo3 ). Several families have lived in it since Peter moved out of it including my wife's grandparents, Willard and Maggie Boyd (photo 4). Lena (Brown) Bear is my aunt having married my Uncle Arthur Bear who had a grocery store in Eldon until he retired in 1965. Lucille is the mother of one of our Miller County Historical Society board members, Donna Carrender. In the photo the women are looking at an old copy of Goodspeed's History of Miller County, published in 1889, which was donated to the museum by Lena. Lucille has donated to the museum an old frock coat worn by the sisters' traveling preacher grandfather, James F. Brown (photo 5).

1 Brown sisters at museum

2 Peter and Joanne Lupardus

3 Lupardus Cabin

4 Willard and Maggie Boyd

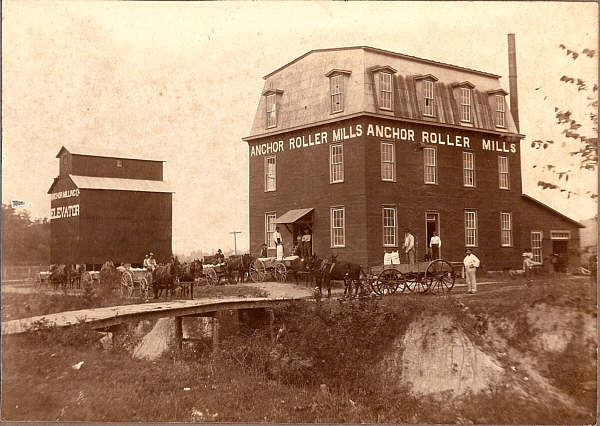

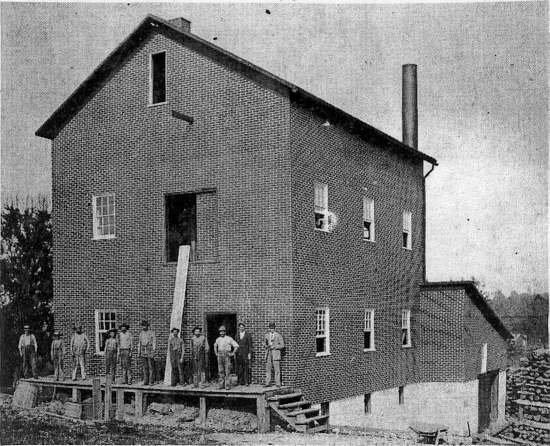

5 Frock Coat of James F. Brown We are progressing in the construction project of the new addition to the museum. The dry wall is almost completed (photo 6 ) and the new roof for the original museum building is expected to be placed next week. Soon we will have the work of moving many of the exhibit items to the new building. We will have quite a job of moving an old mill machine donated by the Anchor Milling Company because it weighs so much (photo 7). This machine was the original corn roller mill for Anchor Mill when the company began business in 1897 (photo 8). It could make corn meal and corn flour. It was powered by a wood fired steam boiler. When the flood of 1943 caused so much damage to Tuscumbia, Anchor Mill decided to move their operations to the top of the hill where the museum building is today. So the old corn roller mill was used at the new location for the next forty years or so using diesel power. The roller mills used for making wheat flour remained under the hill. They were smaller than the corn roller mill and Anchor Mill owned four of them. Since times were changing rapidly after 1943, less and less wheat flour was being made, and by the 1950's only the corn roller mill was being used. Sometime in the 1970's the corn roller mill operation was discontinued. It sat on the porch of the old hardware store building for years getting rusty on the outside. When the museum was moved to the Anchor Mill hardware store building where it is now, the mill was painted and moved to the lower floor. This corn roller mill which now is sitting in our lower level is very heavy; we don't know just now how we will move it to the new building being constructed. We may have to leave it where it is and continue with the Anchor Mill Company display on the lower floor of the museum. The name roller mill comes from the type of mechanism used to grind the grain. Inside the machine are eight cylinders twenty inches long and eight inches wide with grooves that mesh with each cylinder to grind the grain as it is forced through. Bamber Wright, who was one of the executives in the Anchor Milling Company, says that the placing of the rubber belts which turn the wheels on the outside of the grinding area is "tricky" and he is about the only one left who knows how to do it. Another type of milling machine was the "hammer mill" (photo 9). I won't bore you with the mechanical differences between a roller and a hammer mill except to say the roller mill was cheaper to run and more efficient. The one pictured here was used by Anchor Mill at their location in Eldon for many years until it was sold to Pryor Novelty Company (photo 10) for the purpose of grinding cedar wood to make litter for the turkey and poultry farmers in the area.

6 drywall museum 2

7 Roller Mill

8 Old Anchor Mill 1897 steam powered

9 hammer mill for litter

10 Pryor Novelty Company One hundred fifty years ago water mills (photo 11) were used for grinding grain; many of them were present in our county along the spring fed creeks which supplied the power to turn the stones which ground the grain. These mills were simple and had only two big round stones, one on top of the other, to grind the grain. The stones which belonged to the old Wright Mill on Saline creek now are used as an ornamental decoration on the front wall of our museum building (photo 12). C.B. Wright, one of the first officers in Anchor Milling Company, was raised on the farm which had the Wright mill; it was owned by his grandfather James Lawrence Wright and subsequently managed by his father, Green Lee Wright. We are grateful to Bamber Wright, a nephew of C.B. Wright, who has shared many photos and personal information about the Anchor Milling Company as well as his historical knowledge of Tuscumbia and Miller County in general.

11 G.L. Wright carding machine on Saline Creek

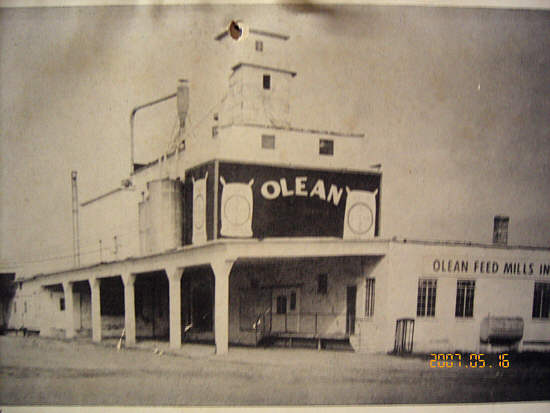

12 mill stone in building wall Other communities acquired roller type mills as well as Tuscumbia including Ulman (photo 13) and Olean. The mill in Olean, owned by the Gattermeir family, was one of the larger operations of its type. The first Gattermeir Mill (photo 14) was started in 1881 by Joe Gattermeir (photo 15) on his home farm near Olean where he improved a mill already present known as the "Buckeye Mill." Unfortunately, it burned in 1895 and a second mill was built (photo 16). But it was destroyed by a tornado of epic proportion in 1916 which also destroyed much of the area around Olean. The last Gattermeir mill (photo 17), was built in Olean in 1916 (the first two as just noted were located on the Gattermeir farm outside of Olean), and ceased operation several years ago. The vacant building recently suffered some damage in a fire this year. We are grateful to Bob Gattermeir for sharing with us information and photos about his family's milling operation in Olean; we will be using the information as part of our display in the new museum about mills in Miller County as well as putting the history of the Gattermeir Mill in a new section on the website soon to come devoted to historic industries and commerce of Miller County.

13 Ulman roller mill

14 First mill on Gattermeir property 1881-1895 destroyed by fire

15 Joseph Gattermeir

16 second mill on Gattermeir property destroyed by tornado

17 Third Gattermeir mill in Olean

I mentioned above that Pryor Novelty Company had bought the old Anchor Mill hammer mill to make litter out of cedar scraps. Later in a future edition of Progress Notes I will discuss in more detail the history of Pryor Novelty Company (old catalogue photo 18) and its production of cedar wood novelties and souvenirs for the tourist trade. However, the story of the way in which Ozark craftsmen used aromatic red cedar wood as well as other types of wood for the purpose of making cabinets, boxes and chests as well as for wood carving is very interesting. James Wright (photo 19), son of artist John Wright, was very good at making chests, boxes and tables out of cedar. The items in the photos are now in the home of Corrine Gilliam, daughter of James (photos 20 and 21). Some time ago I showed a photo of the carving of tools out of cedar with a pocket knife by Barney Flaugher (photo 22). I visited his brother, Harold Flaugher of Eldon/Rocky Mount area the other day and thought I would share all the artistic talent he has for wood working with various kinds of wood. One of his favorite hobbies is making miniature log cabins (photo 23). Another is making miniature horse drawn wagons with the harness for the horses precisely reproduced (photo 24). He can make miniature metal tools (photos 25 and 26). But Harold is best known for his skill in reworking and repairing old fiddles (photos 27). I once bought an old fiddle from Harold's father, Elmer, and Harold refinished it for me such that it almost looks new; and his reworking of it makes it sound rich and full when played. Elmer was a craftsman also as well as being the blacksmith in Tuscumbia years ago. One of Elmer's skills was building John Boats. Harold has made a model of the John Boat that Elmer used to make (photo 28). The John boat had a relatively flat bottom so that it could negotiate the shoals of shallow water with which a boat with a keel would have difficulty. This type of boat was very useful on the Osage River. Not to be ignored for sure is Harold's wife, Joy, who is an artist herself at making decorative quilts (photo 29). Recently, although she always up to now had hand made her quilts, she has been using a machine quilter to speed things up (photo 30). Here is a recent photo of Harold and Joy Flaugher (photo 31).

18 First Color Catalogue Pryor Novelty(1950)

19 James Wright

20 cedar box

21 cedar table

22 Barney Flaugher Exhibit

23 Miniature Log Cabin

24 MiniatureTeam and Wagon

25 Handmade knives

26 Handmade Tools

27 Old German fiddle made with beveled edges

28 Miniature copy of John Boats made by Elmer Flaugher

29 quilt by Joy Flaugher

30 Quilting Machine

31 Harold and Joy Flaugher Continuing my interest in photographing old Miller County log homes this week I took a photo of the James Wall log house located on Mill Creek Road (photo 32). This home is very old and was probably built toward the middle of the nineteenth century since James (who is the great grandfather of Lewis Wall) died about the middle of that century. Another log house is that of William Nelson (photo 33) located west of Iberia.

32 Home of James and Malinda Wall, Mill Creek Road

33 William Nelson Log Home In times past as things evolved and more skills were developed, people started looking for sturdier and longer lasting structures in which to live. One of these was the concrete house. In the old days, the concrete was made from limestone rock dug out of the ground. The rock was heated, pounded into powder, and then mixed with water, sand and gravel to get the mixture needed for construction. Several of these types of buildings can still be found standing in Miller County. These include the James Pemberton house west of Iberia (photos 34-37) and the Oakview Church also west of Iberia (photo 38). The Oakview Church has an interesting history which you can read about as recorded by Peggy Hake in the Churches of Christ part of our Church section which can be found under "Cultural" at the top of the home webpage. You will especially be interested to read there about the grave of the Driver infants which is located behind the church. One concrete house which is not standing is that of Dan Wall (photo 39), grandfather of Lewis Wall, one of our museum volunteers. This house was accidentally dynamited to the ground back in the 1950's when the owner (an executive businessman from St. Louis) decided he wanted to have a basement and used too much explosive to blast a hole out of the ground floor. My wife's grandfather, Frank Steen, had a concrete type house where he lived on the old John Williams farm (photo 40). Unfortunately, it burned to the ground. I have always wondered how a concrete house burned up. I was told by some of those who witnessed it that it took a long time. I would think so.

34 James Pemberton House

35 James Pemberton House

36 front of James Pemberton House

37 Fireplace James Pemberton House

38 Oakview Church of Christ

39 Dan Wall house

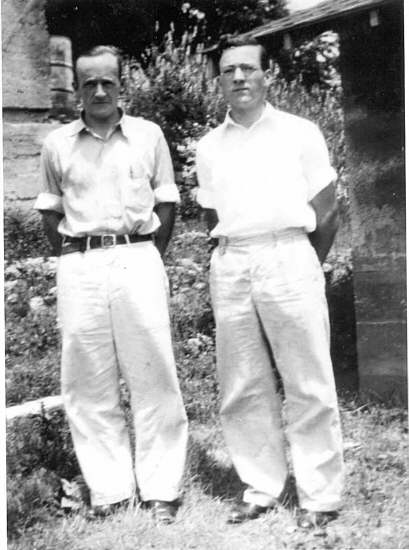

40 Frank Steen House 1913 Once again I will let you read some of the transcript of a conversation between David and Arthur Bear (photo 41) recorded in 1992 in which they discuss how things were done one hundred years ago:

41 Arthur and David Bear

Arthur: David, let's talk about making molasses.

David: Well, we didn't have a sorghum mill on our farm, but each farmer did grow a small field of cane for sorghum molasses. The cane was cut (photo 42) at a time when the sap was at its maximum, and then hauled (photo 43) to one of the neighboring farms where there was a mill. The cane stalks were put in a crusher that squeezed out the sap. The power for the crusher was supplied by a horse that was hitched in a way that he would walk a circle and turn the gears. As the sap flowed out, it would be collected and put in a shallow cooking pan (photo 44) where it was heated to allow much of the water to evaporate. It took experience to know when to stop the cooking. If cooked too much it could affect the taste adversely and also make it too thick. If it was too thick, it was difficult to pour (photo 45). Molasses get thicker when cold, so the old expression developed "It's slower than molasses in January." Sorghum molasses was a staple item for all farm families at that time. Molasses made in this manner was the sweetener used in cooking. Butter and molasses were a delicacy enjoyed by many at every meal. One of our uncles, Theodore Martin, ate molasses three times per day. Each year going in to winter, the farmer tried to have a lot of molasses, cured pork, and lard. Arthur has participated in all these activities too, so do you have anything to say about molasses making Arthur?

42 Cutting Cane

43 gathering the cane

44 Making Molasses

45 Pouring Molasses Into Buckets Arthur: I've seen it all, but never did much. Mon Roberts was the molasses maker in our community. Others who had become well known as molasses makers were Leonard Dixon, Hastings Burks, and Henry Flaugher. Each small community had a molasses maker close by. As you said, molasses was mostly our sugar. I can remember Mom making molasses cookies even just using molasses like she would sugar in much of her cooking.

David: The farmers produced just about everything they ate, and when they went to town, they traded their surplus for other things they couldn't grow on the farm, such as coffee, sugar, salt and things of that nature. Butchering time was an important time on the farm, and this was done, I suppose Arthur, in November or December while the weather was cool enough for meat to keep. They didn't want any spoilage. Why don't you tell us about butchering time on the farm, Arthur?

Editor's note: I don't think I'll mix the making of molasses with the description of "hog killing time" on the farm. Come back next week to read that narrative and see those pictures.

The "What's This" item for this week is somewhat unusual, one of those things that you just had to have done it or seen it before to figure out. However, the puzzle today is something an old sawyer wouldn't have any problem figuring out: (photo 46).

46 What's This Well, this was a block out of a four by six cedar log that my cousin, Tim Pryor, was planing one day and he struck metal which ruined his planer blade. He was very angry but anyway took the time to take a hatchet and cut into the wood to see what it was he struck. And there it was an old mule shoe. Now how did it get there? Well, it didn't pierce the cedar tree by a tornado as someone the other day guessed. What happens to sawyers a lot is that metal objects of one kind or another get picked up by someone and put on a tree branch to get it out of the way and the tree grows around it if it's placed close to the trunk. Most of the time the metal struck by a sawyer would be a piece of barbed wire or a nail. When this happens the sawyer knows it's best to throw the whole log away. Even though that costs him money, the odds are he'll strike more metal somewhere in the rest of the log. Now a mule shoe being grown over by a cedar tree isn't one of those things you would expect to see very often, even for a sawyer. So here it is. You all are some of the first to see it.

Now I hope Tim Pryor never is sold the log of the tree in the next photo after it is sawed down some fifty years from now (photo 47):

47 On the Karr Farm In Iberia Before closing I want to congratulate the Eldon High School which is celebrating this week its one hundredth anniversary. During this time the Eldon school has seen many advancements and programs developed including the Tri-County Technical School which later became the Eldon Career Center; the addition of the new gymnasium, new track, greenhouse, commons and library. My wife and I are very proud to mention that Matt Davis, son of my wife's sister, Janie Davis, has played a significant role in the administration of the Eldon School system over the last few years and now is director of the Career Center.

When I was playing basketball at Tuscumbia High School forty six years ago, I remember going to play in the Eldon Tournament in the old gym (which was the "new" gym at the time). It was so big to all of us guys from Tuscumbia where the school had maybe the smallest basketball gym ever built, that we suffered an acute case of disorientation. Gary Keeth got so tired running back and forth that for a while (until the referee figured it out) he just sat down on the bleacher when the other team took the ball down court and waited until we got the ball at which time he ran back on the court under the basket and got the long pass we threw him to make the easy two points. We might have won if the referee hadn't intervened. But to make the story even more embarrassing, our coach, Fred Umstead, a cousin of mine raised over near Dog Creek south of Tuscumbia, truly got lost for a while before the game and we had to start without him being there for about five minutes. To us from Tuscumbia in those days, Eldon was a big time place (and still is for that matter).

Well, in closing, I want to remind you of our fund raising drive for the building of our new addition to the museum. All donations are appreciated no matter how small. You can mail them to the following address:

Miller County Museum Building Fund

P.O. Box 57

Tuscumbia, Mo. 65082

|